Unveiling the Future of Cooling: How RIGID’s Innovative Solutions are Revolutionizing the Industry

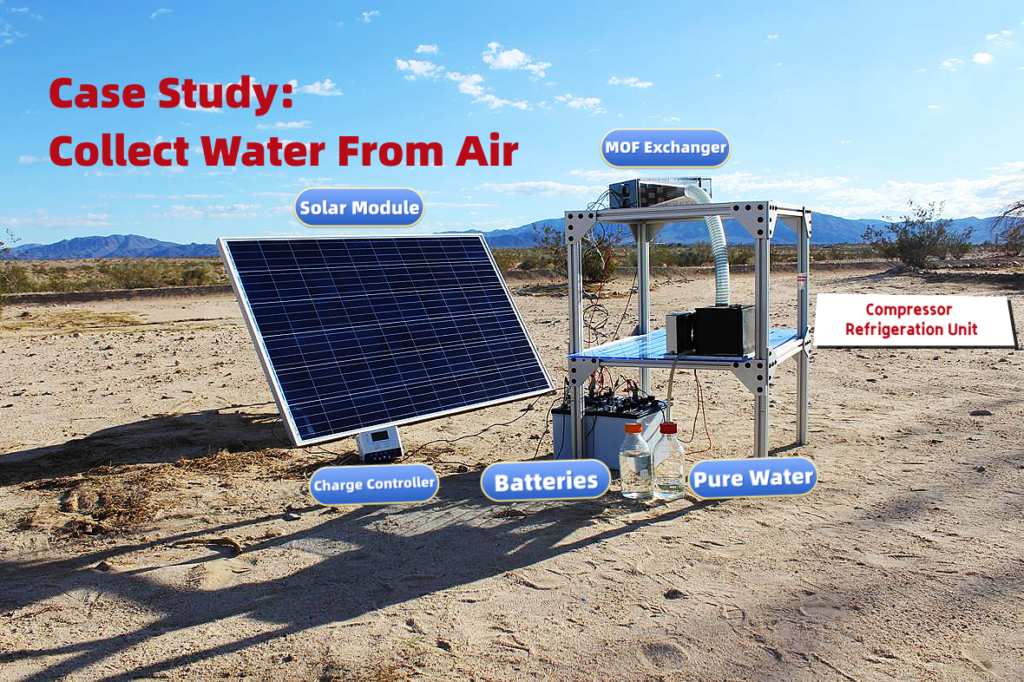

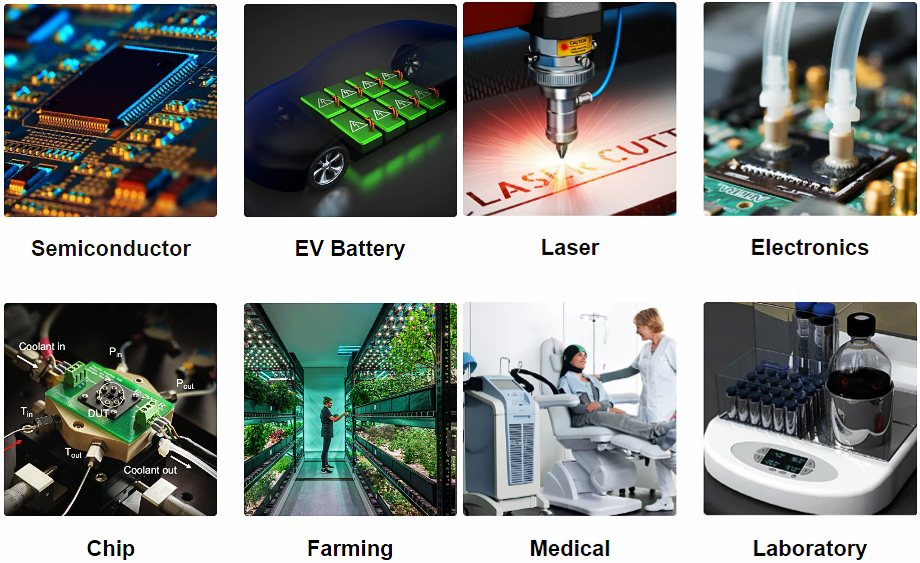

In today’s rapidly advancing industrial landscape, maintaining optimal temperatures for various equipment and processes is crucial. Whether in manufacturing plants, data centers, medical devices, or commercial applications, efficient cooling systems are essential for operational efficiency and longevity. RIGID, a pioneer in cooling technology, has been at the forefront of providing state-of-the-art solutions that cater to these needs. This blog delves into the innovative technologies and products offered by RIGID, focusing on key components such as the miniature DC compressor, compact liquid chiller, and refrigerated cooling systems.

The Evolution of Refrigeration Systems

Understanding Refrigeration Technology

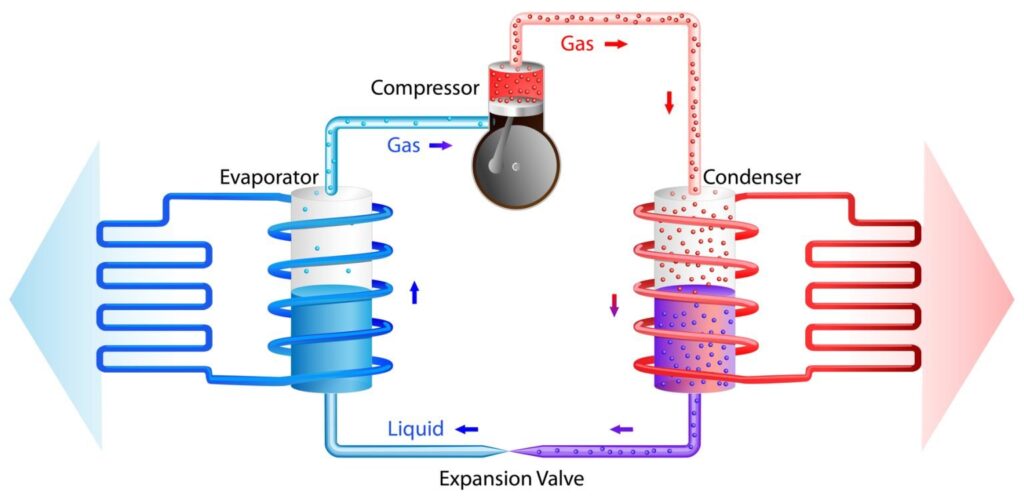

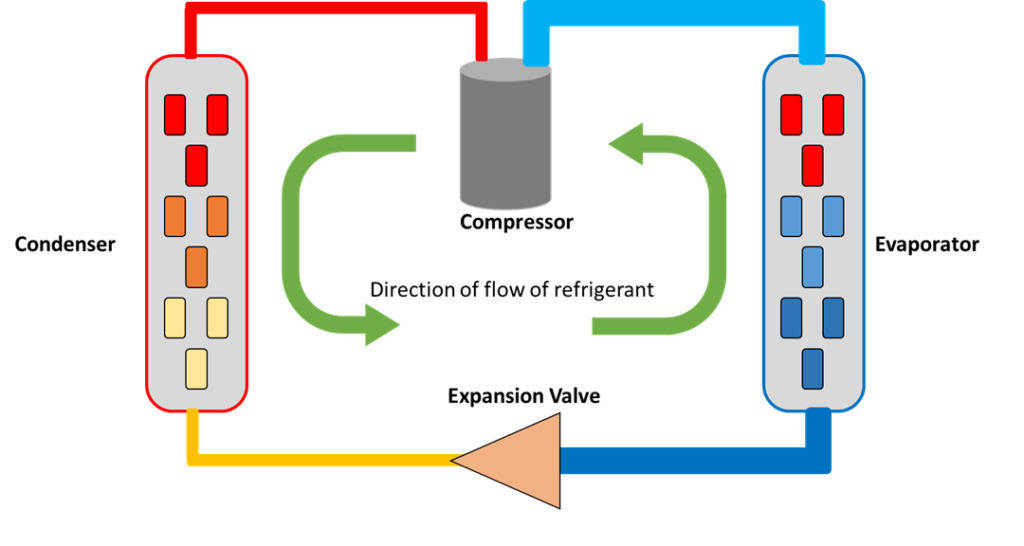

Refrigeration systems are pivotal in various industries for maintaining the desired temperature of equipment and processes. The core of these systems lies in the vapour compression refrigeration system, a widely used method for effective cooling. This system works by compressing a refrigerant gas, which then dissipates heat as it condenses into a liquid. This refrigerant liquid absorbs heat from the surroundings as it evaporates, providing the necessary cooling effect.

RIGID’s Advanced Refrigeration Systems

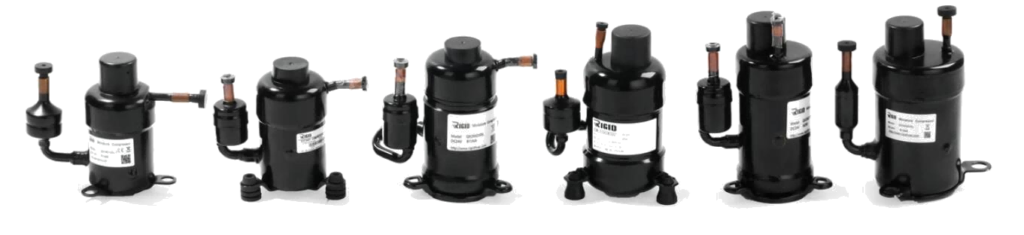

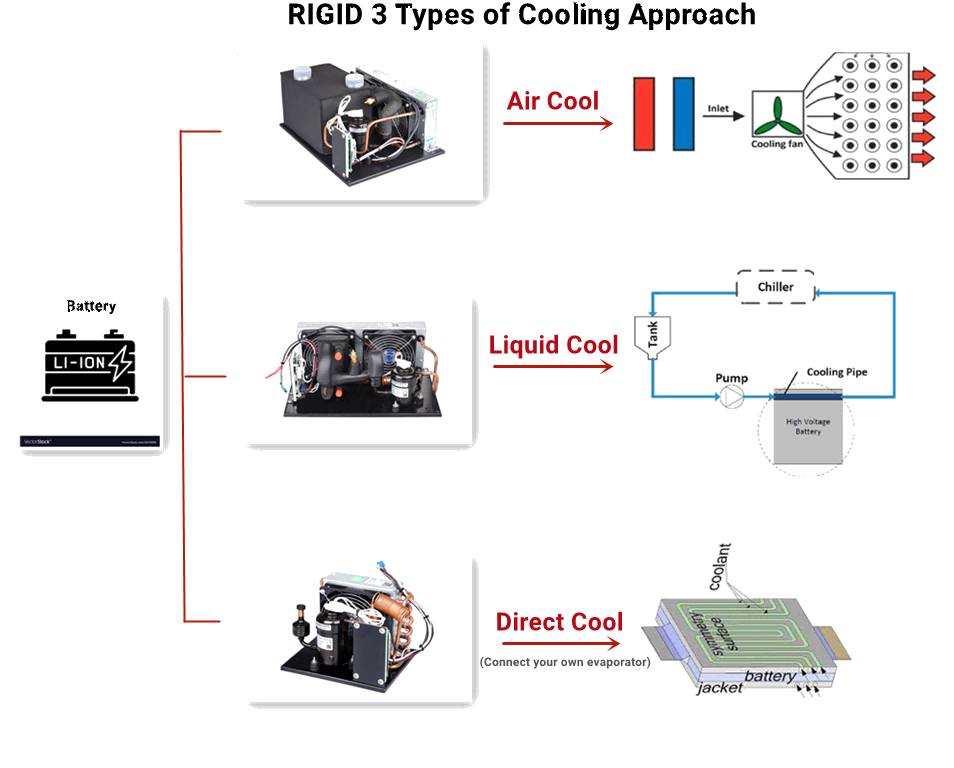

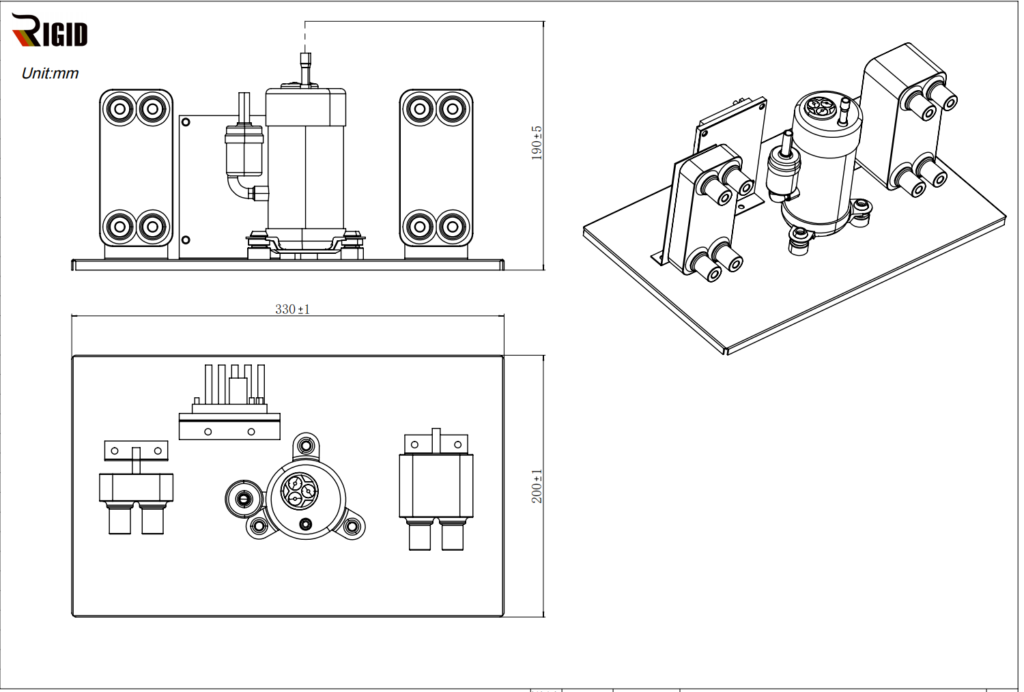

RIGID’s refrigeration systems are designed with cutting-edge technology to ensure superior performance and reliability. The miniature DC compressor is a standout component, enabling compact and efficient cooling solutions. Unlike traditional compressors, the miniature DC compressor operates with lower energy consumption and higher precision, making it ideal for small and intricate applications.

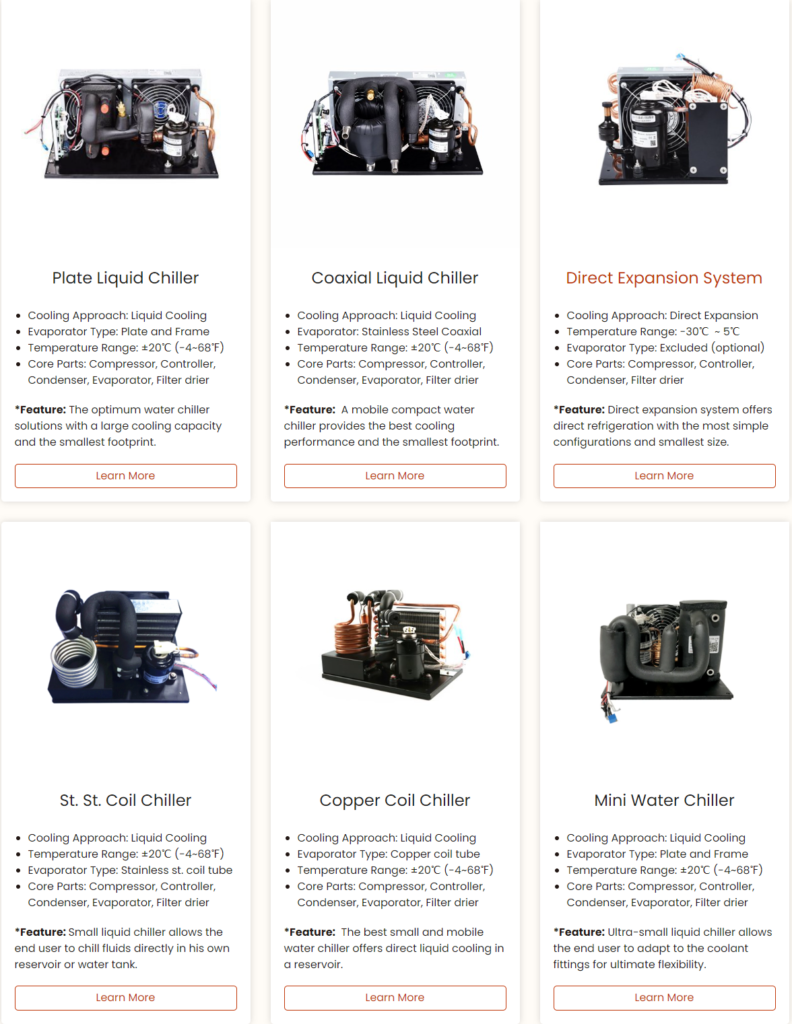

Compact Liquid Chillers: The Backbone of Efficient Cooling

Why Choose Compact Liquid Chillers?

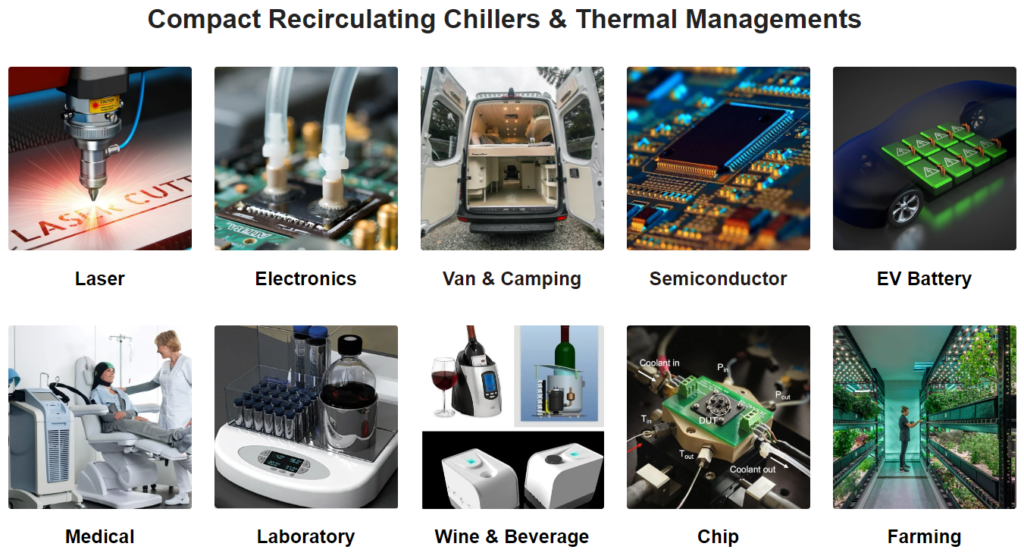

Compact liquid chillers are essential for applications where space is limited, and precise temperature control is required. RIGID’s compact liquid chillers are designed to deliver high performance in a small footprint, making them perfect for diverse applications, including medical device cooling and industrial equipment.

Features and Benefits

- Energy Efficiency: RIGID’s compact liquid chillers consume less energy, reducing operational costs and environmental impact.

- Reliability: Built with high-quality materials and advanced technology, these chillers offer long-term reliability and minimal maintenance.

- Versatility: Suitable for a wide range of applications, from cooling electronic components to maintaining optimal temperatures in medical devices.

Refrigerated Cooling Systems: A Closer Look

The Mechanics of Refrigerated Cooling

Refrigerated cooling systems are integral to maintaining consistent temperatures in various applications. These systems work by using a refrigeration cooling system to transfer heat away from the equipment, ensuring it operates within safe temperature ranges. The fluid chillers used in these systems play a critical role in this process.

RIGID’s Refrigerated Cooling Solutions

RIGID offers a range of refrigerated cooling systems designed to meet the specific needs of different industries. Their systems are known for their efficiency, reliability, and ease of integration.

- Fluid Chillers: RIGID’s fluid chillers are designed to provide precise temperature control, ensuring optimal performance of the equipment they cool.

- Cold Plate Refrigeration System: This system is particularly useful for applications requiring direct contact cooling, such as in electronic devices and medical equipment.

Specialized Cooling Systems for Niche Applications

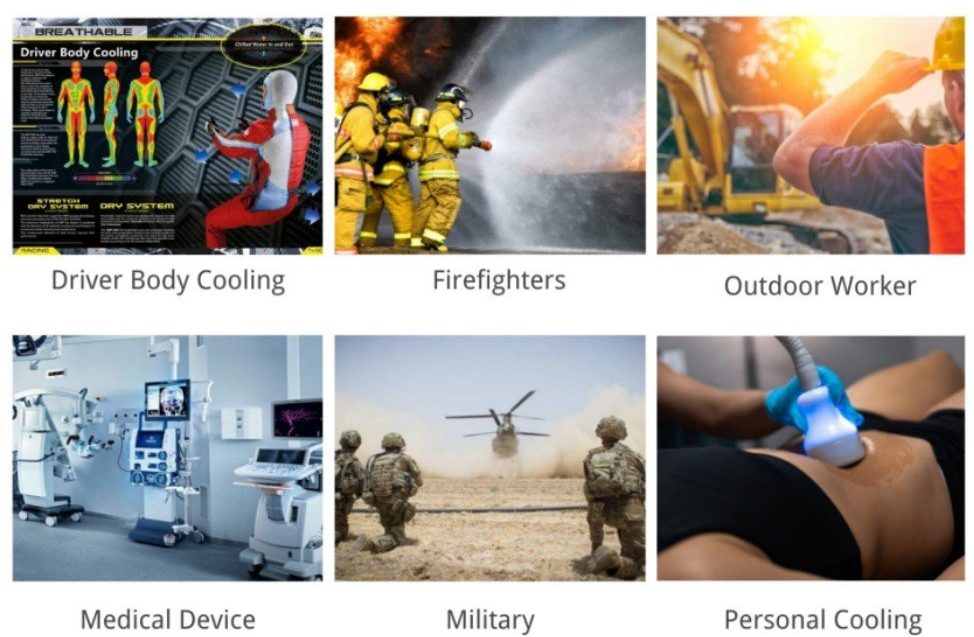

Medical Device Cooling

In the medical field, maintaining the precise temperature of devices is critical for their functionality and safety. RIGID’s medical device cooling solutions are tailored to meet these stringent requirements. The compact and efficient design of these systems ensures that medical devices operate reliably and safely.

Closed Loop Water Cooling Systems

For applications requiring a closed system to prevent contamination and ensure consistent cooling, RIGID’s closed loop water cooling system is an ideal choice. This system recirculates the cooling water, providing efficient heat removal without the risk of external contamination.

The Future of Cooling: Micro and Vapor Cooling Units

Micro Cooling Units

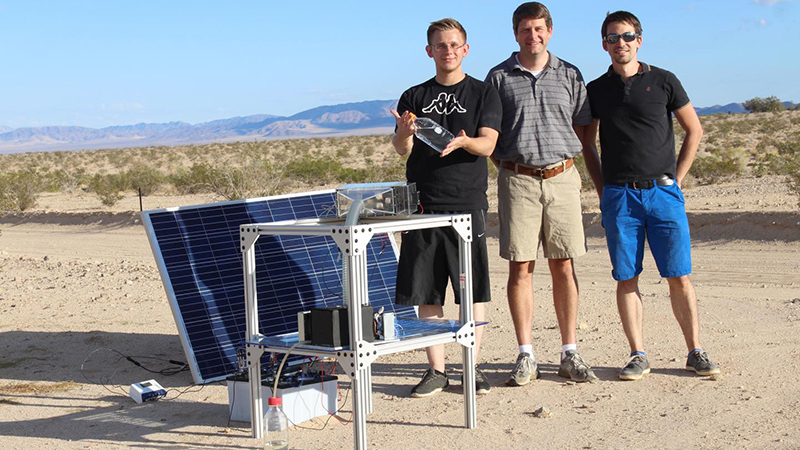

As technology advances, the demand for smaller and more efficient cooling solutions grows. RIGID’s micro cooling units are designed to meet this demand. These units are compact, yet powerful, providing effective cooling for small-scale applications.

Vapor Cooling Systems

RIGID’s vapor cooling system represents the next step in efficient and compact cooling solutions. By utilizing the principles of vapor compression, these systems provide high-performance cooling in a small footprint, making them ideal for advanced electronic devices and other high-precision applications.

Conclusion

RIGID’s innovative cooling solutions are transforming the way industries manage temperature control. From the miniature DC compressor to the compact liquid chiller and refrigerated cooling systems, RIGID’s products are designed to meet the diverse needs of modern applications. Whether it’s for industrial equipment, medical devices, or specialized applications, RIGID’s cooling systems offer unparalleled efficiency, reliability, and performance.

By continually pushing the boundaries of cooling technology, RIGID is not only meeting the current demands but also paving the way for future innovations. Their commitment to excellence and customer satisfaction ensures that they remain a leader in the cooling industry, providing solutions that enhance productivity, efficiency, and safety across various sectors.

Explore RIGID’s range of products and discover how their advanced cooling systems can benefit your applications. With RIGID, you can trust that your cooling needs are in expert hands, backed by cutting-edge technology and a dedication to quality.

In this blog, we have explored the various aspects of RIGID’s cooling solutions, from their miniature DC compressor and compact liquid chiller to their advanced refrigerated cooling systems. By understanding the mechanics and benefits of these systems, industries can make informed decisions to enhance their operational efficiency and longevity. As we look to the future, RIGID’s continuous innovation and commitment to excellence ensure that they will remain at the forefront of the cooling industry, providing solutions that meet the evolving needs of modern applications.

Exploring the Innovations and Applications of RIGID’s Advanced Cooling Technologies

In today’s rapidly evolving industrial landscape, efficient and reliable cooling solutions are paramount. Whether it’s in manufacturing, medical devices, or data centers, the need for maintaining optimal temperatures is critical for operational efficiency and equipment longevity. RIGID, a leader in cooling technology, has been at the forefront of providing advanced solutions such as miniature DC compressors, compact liquid chillers, and comprehensive refrigeration systems. This blog delves into the intricacies of RIGID’s cooling technologies, exploring their benefits, applications, and the innovations driving their success.

The Miniature DC Compressor: A Game-Changer in Cooling Technology

One of RIGID’s standout innovations is the miniature DC compressor. These compact yet powerful devices are designed to provide efficient cooling in a small footprint. Their size makes them ideal for applications where space is at a premium, such as in medical devices and portable cooling systems.

The miniature DC compressor operates using a vapor compression refrigeration system, which is known for its efficiency and reliability. By compressing the refrigerant vapor, it increases the pressure and temperature of the refrigerant, which is then condensed into a liquid. This process releases heat and is fundamental to the cooling cycle.

Benefits of Miniature DC Compressors

- Compact Size: Their small form factor allows them to be integrated into a variety of devices without requiring significant space.

- Energy Efficiency: These compressors are designed to consume less power, making them ideal for battery-operated and portable devices.

- Low Noise: Advanced engineering ensures that these compressors operate quietly, an essential feature for applications in medical and residential environments.

Compact Liquid Chillers: Efficient and Versatile Cooling Solutions

RIGID’s compact liquid chillers are another cornerstone of their product lineup. These systems are designed to deliver precise and consistent cooling for a variety of applications, from industrial machinery to laboratory equipment. Utilizing a refrigerated cooling approach, these chillers ensure that the temperature is maintained within strict tolerances, which is crucial for sensitive processes.

Key Features of Compact Liquid Chillers

- High Efficiency: By leveraging the principles of the vapour compression refrigeration system, these chillers achieve high cooling efficiency while minimizing energy consumption.

- Reliability: Built with robust components, RIGID’s liquid chillers are designed to operate reliably in demanding environments.

- Flexibility: Available in various configurations, these chillers can be customized to meet specific cooling requirements, making them suitable for a wide range of applications.

The Science Behind Refrigeration Systems

At the heart of RIGID’s cooling technologies is the refrigeration system. This system plays a crucial role in maintaining the desired temperature by transferring heat from one area to another using a refrigerant. The process involves several key components, including the compressor, condenser, expansion valve, and evaporator.

The Role of Refrigerant Liquid

The refrigerant liquid is a vital component of the refrigeration system. It undergoes phase changes from liquid to vapor and back to liquid, absorbing and releasing heat in the process. The choice of refrigerant is critical, as it affects the efficiency and environmental impact of the system.

RIGID’s systems are designed to use environmentally friendly refrigerants, aligning with global efforts to reduce greenhouse gas emissions. This commitment to sustainability ensures that their products not only deliver exceptional performance but also contribute to environmental conservation.

Fluid Chillers: Precision Cooling for Industrial Applications

Fluid chillers are essential in industrial settings where precise temperature control is required. These systems use a liquid coolant to absorb heat from equipment and processes, ensuring that they operate within safe temperature limits. RIGID’s fluid chillers are renowned for their accuracy and reliability.

Applications of Fluid Chillers

- Manufacturing: In industries such as plastics and metalworking, fluid chillers maintain the optimal temperature of machinery and materials, enhancing product quality and process efficiency.

- Laser Cooling: Precision cooling is crucial for laser systems to ensure stable performance and prevent overheating.

- Medical Equipment: Sensitive medical devices, such as MRI machines and laboratory instruments, rely on fluid chillers for consistent and reliable cooling.

The Versatility of Refrigeration Cooling Systems

RIGID’s refrigeration cooling systems are designed to be versatile and adaptable to various applications. These systems integrate seamlessly into existing setups and provide efficient cooling for diverse needs.

Advantages of RIGID’s Refrigeration Cooling Systems

- Customizable: RIGID offers a range of systems that can be tailored to specific requirements, ensuring optimal performance for any application.

- Efficient Heat Removal: By employing advanced cooling techniques, these systems effectively remove heat, enhancing the longevity and reliability of equipment.

- Low Maintenance: Designed with durability in mind, RIGID’s cooling systems require minimal maintenance, reducing operational costs and downtime.

Liquid Chillers: Compact and Powerful Cooling Units

Liquid chillers are a core component of RIGID’s product offering. These units are engineered to provide powerful cooling in a compact form factor, making them ideal for applications where space is limited.

Features of RIGID’s Liquid Chillers

- Compact Design: Despite their small size, RIGID’s liquid chillers deliver impressive cooling performance.

- Energy Efficient: These chillers are designed to maximize cooling efficiency while minimizing energy consumption.

- Reliable Operation: Built with high-quality components, RIGID’s liquid chillers ensure consistent and reliable performance.

Small Cooling Systems: Big Impact in a Small Package

RIGID’s small cooling systems are perfect for applications where size and weight are critical considerations. These systems are used in various industries, from electronics to medical devices, providing reliable cooling without taking up significant space.

Applications of Small Cooling Systems

- Electronics Cooling: Ensuring that electronic components operate within safe temperature ranges is crucial for their longevity and performance.

- Portable Medical Devices: Small cooling systems are essential for portable medical devices, providing reliable cooling on the go.

- Laboratory Equipment: Precision cooling is required for many types of laboratory equipment to ensure accurate results and prevent overheating.

Micro Cooling Units: Precision Cooling for Small Applications

Micro cooling units are another innovative solution from RIGID. These units are designed for applications requiring precise cooling in a very small footprint.

Benefits of Micro Cooling Units

- Ultra-Compact: These units are incredibly small, making them ideal for applications with severe space constraints.

- Precision Cooling: Despite their size, micro cooling units provide precise temperature control, essential for sensitive applications.

- Low Power Consumption: Designed to be energy-efficient, these units are perfect for battery-operated devices and other low-power applications.

Vapor Cooling Systems: Efficient Heat Removal

RIGID’s vapor cooling systems utilize the principles of vapor compression to achieve efficient heat removal. These systems are ideal for applications where high-efficiency cooling is required.

Key Advantages of Vapor Cooling Systems

- High Efficiency: By using the vapor compression cycle, these systems achieve high cooling efficiency.

- Reliable Performance: Built with robust components, RIGID’s vapor cooling systems ensure reliable operation.

- Versatility: Suitable for a wide range of applications, these systems can be customized to meet specific cooling needs.

Cold Plate Refrigeration Systems: Direct Cooling for High-Heat Applications

Cold plate refrigeration systems provide direct cooling for applications with high heat generation. These systems use cold plates to absorb and dissipate heat, ensuring that equipment remains within safe temperature limits.

Applications of Cold Plate Refrigeration Systems

- Power Electronics: High-power electronic devices generate significant heat, which can be efficiently managed using cold plate refrigeration systems.

- Aerospace: Precision cooling is critical in aerospace applications to ensure the reliability and performance of electronic components.

- Medical Devices: Cold plates are used in medical devices to provide direct and efficient cooling, ensuring consistent performance.

Medical Device Cooling: Ensuring Reliability and Performance

Cooling is critical in the medical field, where equipment reliability and performance can have direct impacts on patient care. RIGID’s cooling solutions are designed to meet the stringent requirements of medical device cooling.

Importance of Medical Device Cooling

- Reliability: Medical devices must operate reliably under all conditions, and effective cooling is essential to prevent overheating.

- Precision: Many medical devices require precise temperature control to ensure accurate readings and results.

- Safety: Proper cooling helps maintain the safety and integrity of medical devices, protecting both patients and healthcare professionals.

Closed Loop Water Cooling Systems: Efficient and Sustainable Cooling

RIGID’s closed loop water cooling systems are designed for applications requiring efficient and sustainable cooling. These systems use a closed loop to circulate coolant, providing consistent and reliable temperature control.

Benefits of Closed Loop Water Cooling Systems

- Efficiency: By recirculating the coolant, these systems achieve high cooling efficiency while minimizing water usage.

- Sustainability: Closed loop systems are environmentally friendly, reducing the need for constant water replenishment.

- Low Maintenance: Designed to operate with minimal maintenance, these systems reduce operational costs and downtime.

Conclusion

RIGID’s advanced cooling technologies, including miniature DC compressors, compact liquid chillers, and vapor cooling systems, represent the cutting edge of refrigeration technology. These solutions are designed to provide efficient, reliable, and sustainable cooling across a wide range of applications, from industrial machinery to medical devices. By leveraging innovative design and advanced engineering, RIGID continues to set the standard for high-performance cooling systems, ensuring that their clients can maintain optimal temperatures and protect their valuable equipment. Whether you need precision cooling for a sensitive medical device or robust cooling for industrial machinery, RIGID’s diverse product lineup offers the perfect solution to meet your specific needs.

Exploring the Innovations and Applications of RIGID’s Advanced Cooling Technologies

In today’s rapidly evolving industrial landscape, efficient and reliable cooling solutions are paramount. Whether it’s in manufacturing, medical devices, or data centers, the need for maintaining optimal temperatures is critical for operational efficiency and equipment longevity. RIGID, a leader in cooling technology, has been at the forefront of providing advanced solutions such as miniature DC compressors, compact liquid chillers, and comprehensive refrigeration systems. This blog delves into the intricacies of RIGID’s cooling technologies, exploring their benefits, applications, and the innovations driving their success.

The Miniature DC Compressor: A Game-Changer in Cooling Technology

One of RIGID’s standout innovations is the miniature DC compressor. These compact yet powerful devices are designed to provide efficient cooling in a small footprint. Their size makes them ideal for applications where space is at a premium, such as in medical devices and portable cooling systems.

The miniature DC compressor operates using a vapor compression refrigeration system, which is known for its efficiency and reliability. By compressing the refrigerant vapor, it increases the pressure and temperature of the refrigerant, which is then condensed into a liquid. This process releases heat and is fundamental to the cooling cycle.

Benefits of Miniature DC Compressors

- Compact Size: Their small form factor allows them to be integrated into a variety of devices without requiring significant space.

- Energy Efficiency: These compressors are designed to consume less power, making them ideal for battery-operated and portable devices.

- Low Noise: Advanced engineering ensures that these compressors operate quietly, an essential feature for applications in medical and residential environments.

Compact Liquid Chillers: Efficient and Versatile Cooling Solutions

RIGID’s compact liquid chillers are another cornerstone of their product lineup. These systems are designed to deliver precise and consistent cooling for a variety of applications, from industrial machinery to laboratory equipment. Utilizing a refrigerated cooling approach, these chillers ensure that the temperature is maintained within strict tolerances, which is crucial for sensitive processes.

Key Features of Compact Liquid Chillers

- High Efficiency: By leveraging the principles of the vapour compression refrigeration system, these chillers achieve high cooling efficiency while minimizing energy consumption.

- Reliability: Built with robust components, RIGID’s liquid chillers are designed to operate reliably in demanding environments.

- Flexibility: Available in various configurations, these chillers can be customized to meet specific cooling requirements, making them suitable for a wide range of applications.

The Science Behind Refrigeration Systems

At the heart of RIGID’s cooling technologies is the refrigeration system. This system plays a crucial role in maintaining the desired temperature by transferring heat from one area to another using a refrigerant. The process involves several key components, including the compressor, condenser, expansion valve, and evaporator.

The Role of Refrigerant Liquid

The refrigerant liquid is a vital component of the refrigeration system. It undergoes phase changes from liquid to vapor and back to liquid, absorbing and releasing heat in the process. The choice of refrigerant is critical, as it affects the efficiency and environmental impact of the system.

RIGID’s systems are designed to use environmentally friendly refrigerants, aligning with global efforts to reduce greenhouse gas emissions. This commitment to sustainability ensures that their products not only deliver exceptional performance but also contribute to environmental conservation.

Fluid Chillers: Precision Cooling for Industrial Applications

Fluid chillers are essential in industrial settings where precise temperature control is required. These systems use a liquid coolant to absorb heat from equipment and processes, ensuring that they operate within safe temperature limits. RIGID’s fluid chillers are renowned for their accuracy and reliability.

Applications of Fluid Chillers

- Manufacturing: In industries such as plastics and metalworking, fluid chillers maintain the optimal temperature of machinery and materials, enhancing product quality and process efficiency.

- Laser Cooling: Precision cooling is crucial for laser systems to ensure stable performance and prevent overheating.

- Medical Equipment: Sensitive medical devices, such as MRI machines and laboratory instruments, rely on fluid chillers for consistent and reliable cooling.

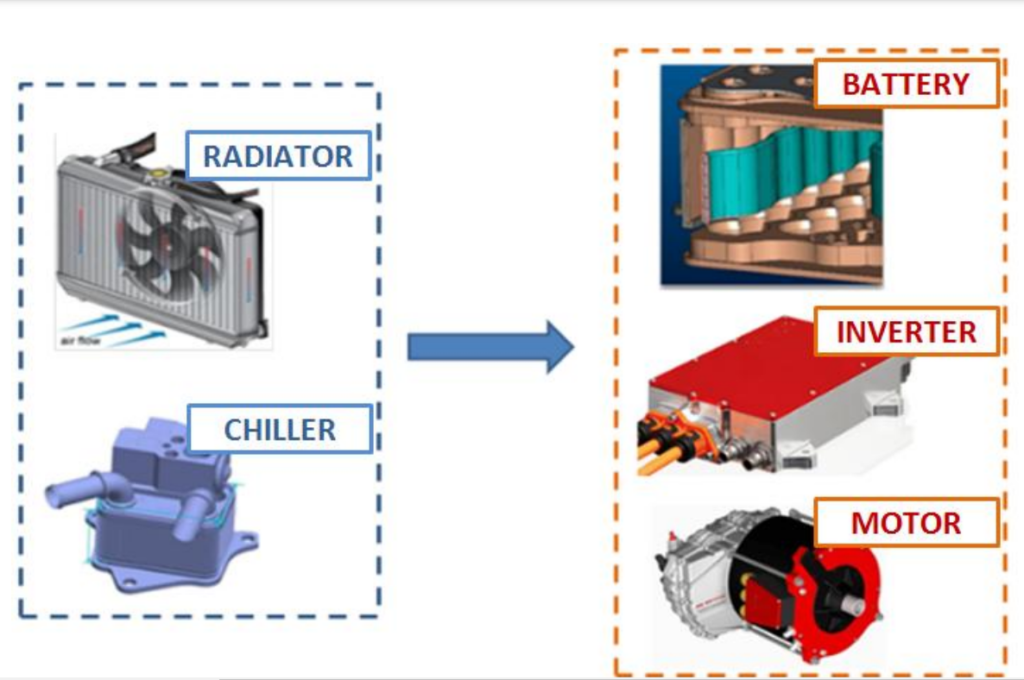

12V Water Chiller for High-power Powertrain System Cooling – RIGID

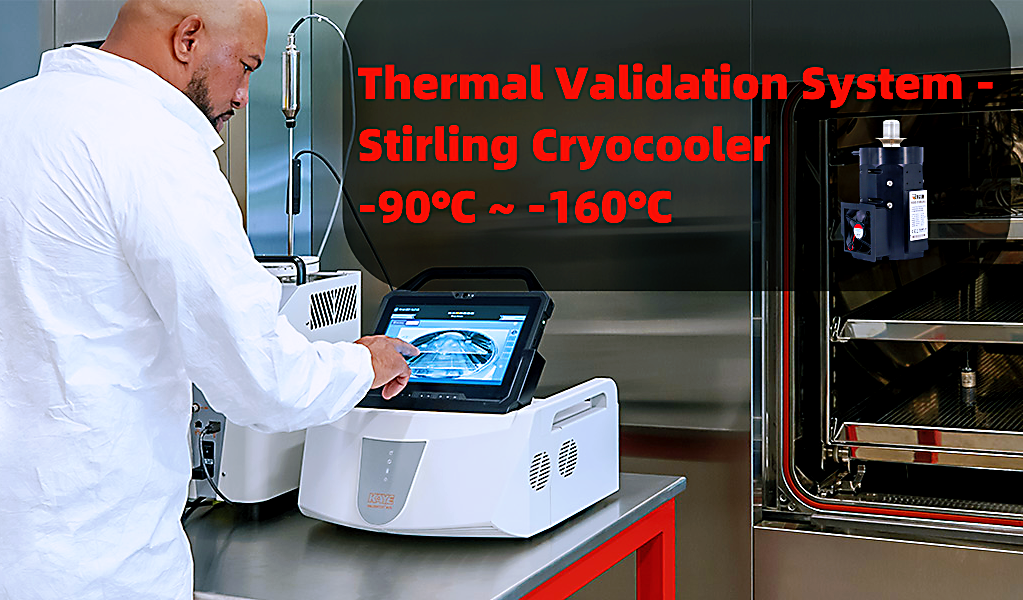

Thermal Validation System Cooling – Thermal Management – RIGID Stirling Cryocooler

The Versatility of Refrigeration Cooling Systems

RIGID’s refrigeration cooling systems are designed to be versatile and adaptable to various applications. These systems integrate seamlessly into existing setups and provide efficient cooling for diverse needs.

Advantages of RIGID’s Refrigeration Cooling Systems

- Customizable: RIGID offers a range of systems that can be tailored to specific requirements, ensuring optimal performance for any application.

- Efficient Heat Removal: By employing advanced cooling techniques, these systems effectively remove heat, enhancing the longevity and reliability of equipment.

- Low Maintenance: Designed with durability in mind, RIGID’s cooling systems require minimal maintenance, reducing operational costs and downtime.

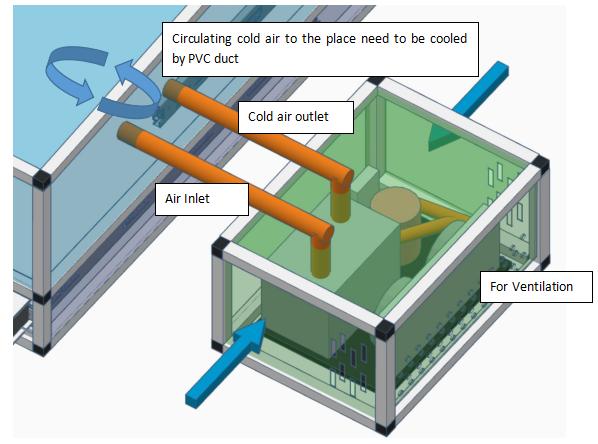

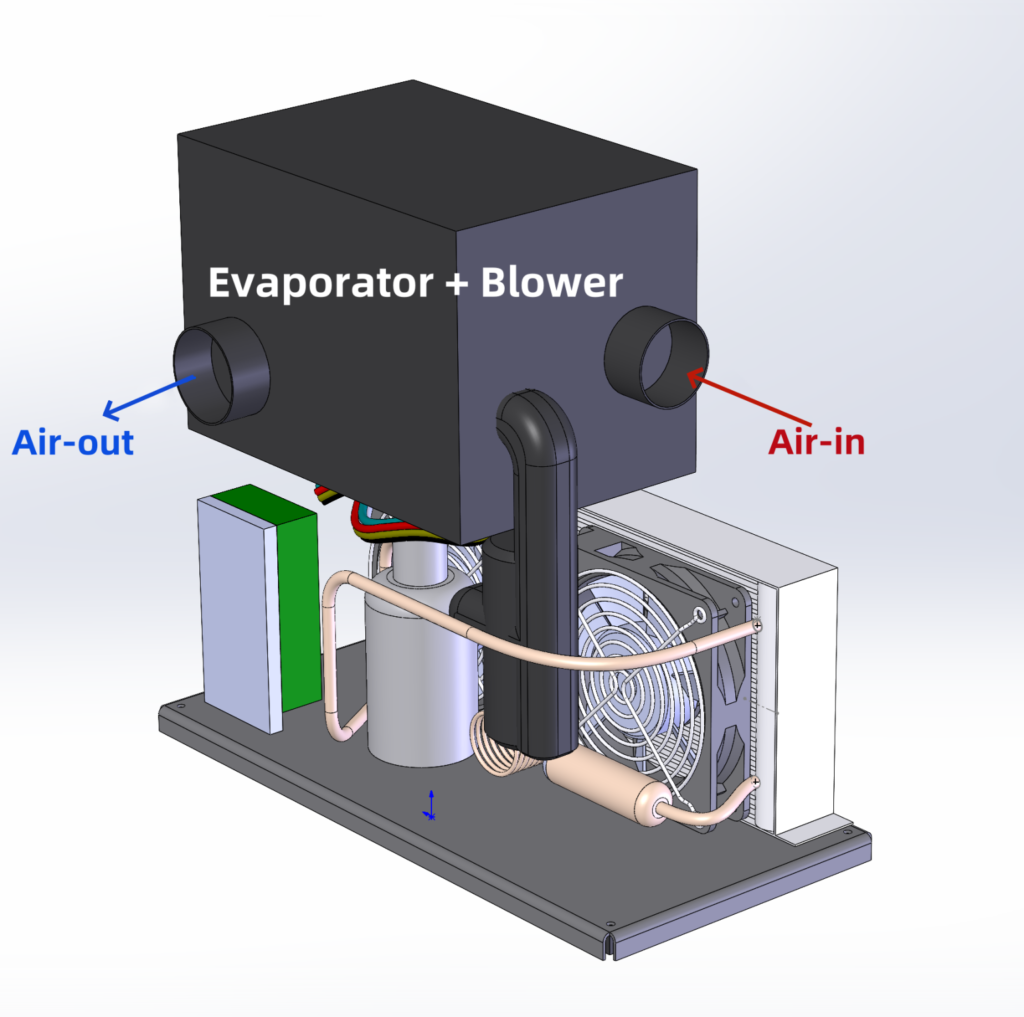

12V DC Micro Aircon_RIGID

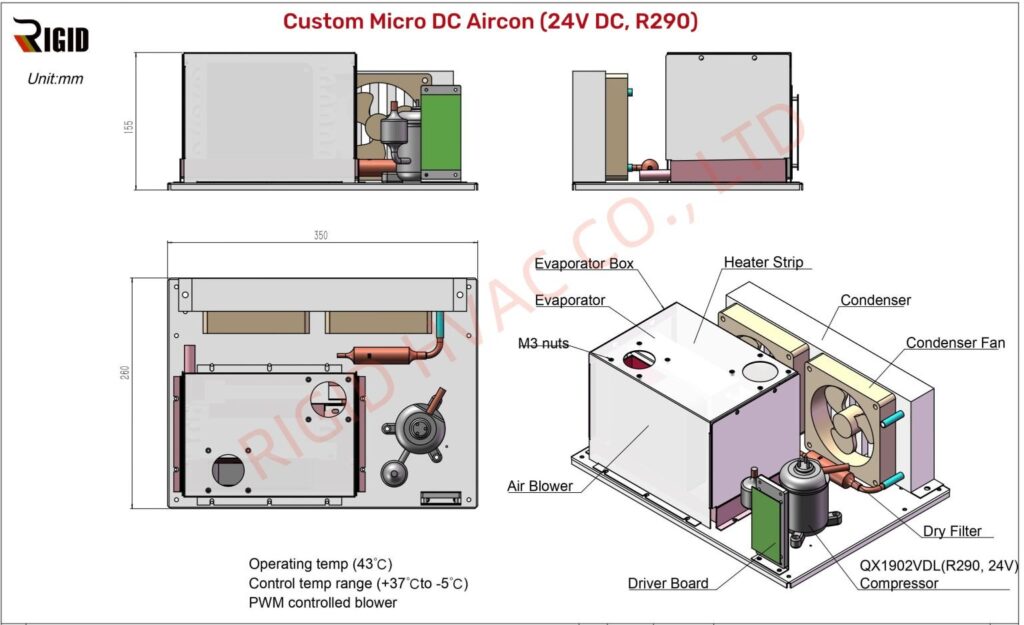

Custom Micro DC Aircon – RIGID

Liquid Chillers: Compact and Powerful Cooling Units

Liquid chillers are a core component of RIGID’s product offering. These units are engineered to provide powerful cooling in a compact form factor, making them ideal for applications where space is limited.

Features of RIGID’s Liquid Chillers

- Compact Design: Despite their small size, RIGID’s liquid chillers deliver impressive cooling performance.

- Energy Efficient: These chillers are designed to maximize cooling efficiency while minimizing energy consumption.

- Reliable Operation: Built with high-quality components, RIGID’s liquid chillers ensure consistent and reliable performance.

Small Cooling Systems: Big Impact in a Small Package

RIGID’s small cooling systems are perfect for applications where size and weight are critical considerations. These systems are used in various industries, from electronics to medical devices, providing reliable cooling without taking up significant space.

Applications of Small Cooling Systems

- Electronics Cooling: Ensuring that electronic components operate within safe temperature ranges is crucial for their longevity and performance.

- Portable Medical Devices: Small cooling systems are essential for portable medical devices, providing reliable cooling on the go.

- Laboratory Equipment: Precision cooling is required for many types of laboratory equipment to ensure accurate results and prevent overheating.

Micro Cooling Units: Precision Cooling for Small Applications

Micro cooling units are another innovative solution from RIGID. These units are designed for applications requiring precise cooling in a very small footprint.

Benefits of Micro Cooling Units

- Ultra-Compact: These units are incredibly small, making them ideal for applications with severe space constraints.

- Precision Cooling: Despite their size, micro cooling units provide precise temperature control, essential for sensitive applications.

- Low Power Consumption: Designed to be energy-efficient, these units are perfect for battery-operated devices and other low-power applications.

Mini Water Chiller a cooling solution to Chemo

Vapor Cooling Systems: Efficient Heat Removal

RIGID’s vapor cooling systems utilize the principles of vapor compression to achieve efficient heat removal. These systems are ideal for applications where high-efficiency cooling is required.

Key Advantages of Vapor Cooling Systems

- High Efficiency: By using the vapor compression cycle, these systems achieve high cooling efficiency.

- Reliable Performance: Built with robust components, RIGID’s vapor cooling systems ensure reliable operation.

- Versatility: Suitable for a wide range of applications, these systems can be customized to meet specific cooling needs.

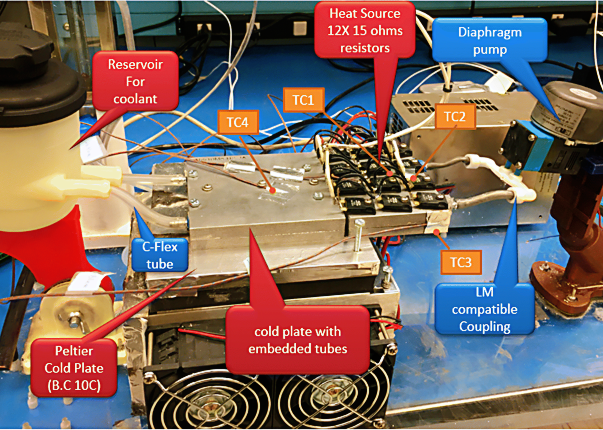

Cold Plate Refrigeration Systems: Direct Cooling for High-Heat Applications

Cold plate refrigeration systems provide direct cooling for applications with high heat generation. These systems use cold plates to absorb and dissipate heat, ensuring that equipment remains within safe temperature limits.

closed recirculating cooling water system-RIGID HVAC

Applications of Cold Plate Refrigeration Systems

- Power Electronics: High-power electronic devices generate significant heat, which can be efficiently managed using cold plate refrigeration systems.

- Aerospace: Precision cooling is critical in aerospace applications to ensure the reliability and performance of electronic components.

- Medical Devices: Cold plates are used in medical devices to provide direct and efficient cooling, ensuring consistent performance.

Medical Device Cooling: Ensuring Reliability and Performance

Cooling is critical in the medical field, where equipment reliability and performance can have direct impacts on patient care. RIGID’s cooling solutions are designed to meet the stringent requirements of medical device cooling.

Importance of Medical Device Cooling

- Reliability: Medical devices must operate reliably under all conditions, and effective cooling is essential to prevent overheating.

- Precision: Many medical devices require precise temperature control to ensure accurate readings and results.

- Safety: Proper cooling helps maintain the safety and integrity of medical devices, protecting both patients and healthcare professionals.

Closed Loop Water Cooling Systems: Efficient and Sustainable Cooling

RIGID’s closed loop water cooling systems are designed for applications requiring efficient and sustainable cooling. These systems use a closed loop to circulate coolant, providing consistent and reliable temperature control.

Benefits of Closed Loop Water Cooling Systems

- Efficiency: By recirculating the coolant, these systems achieve high cooling efficiency while minimizing water usage.

- Sustainability: Closed loop systems are environmentally friendly, reducing the need for constant water replenishment.

- Low Maintenance: Designed to operate with minimal maintenance, these systems reduce operational costs and downtime.

Battery Cooling System – RIGID 12V Water Chiller

Conclusion

RIGID’s advanced cooling technologies, including Miniature DC Compressors, Compact Liquid Chillers, and Micro DC Aircon, represent the cutting edge of refrigeration technology. These solutions are designed to provide efficient, reliable, and sustainable cooling across a wide range of applications, from industrial machinery to medical devices. By leveraging innovative design and advanced engineering, RIGID continues to set the standard for high-performance cooling systems, ensuring that their clients can maintain optimal temperatures and protect their valuable equipment. Whether you need precision cooling for a sensitive medical device or robust cooling for industrial machinery, RIGID’s diverse product lineup offers the perfect solution to meet your specific needs.