Micro DC Airon-Cool

Micro DC Airon-Cool

As a spot cooler designed for confined/small space cooling, small footprint, and less power consumption.

- 12V/24V/48V DC

- R134a /R290 refrigerant

- Brushless direct-current compressor

- Small in size, compact like A4 paper

- 2,000~6,500 rpm variable speed adjustment

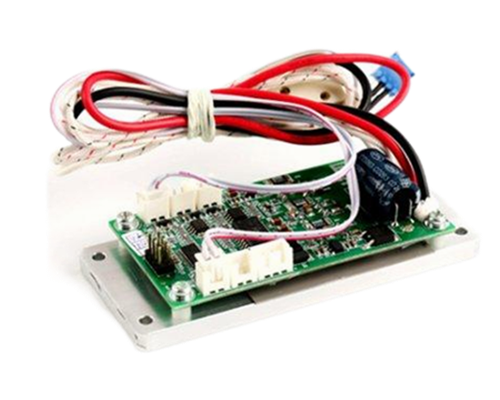

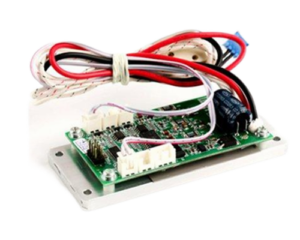

- Drive board (PCB) included for controls and software

RIGID: Your Unique Micro DC Air Conditioner Supplier

RIGID Micro DC Aircon is a compact solution for small & confined space cooling, such as cabins, cuddy cabins, and electric vehicles, etc. The mobile A/C unit runs on power DC 12V/24V/ 48V, easily connecting to challenging confined spaces and extremely hot ambient!

This micro dc aircon is a sub-system that can be easily integrated into the customer’s system and device. And its smallest footprint and lightest weight make it a perfect match for their compact space cooling. The portable Micro DC A/C is often used in small spaces such as RVs, vans, boats, camper trailers, vehicles, tents, and portable coolers, as well as for cooling electronic equipment and telecommunications systems. They can be powered by batteries or through a DC power source such as batteries, DC power, and solar power and are designed to be compact, lightweight, and easy to install.

RIGID Micro DC Air conditioner unit (DC stands for direct current) built with a BLDC (brushless direct current) miniature vapor compressor is a type of small-scale air conditioning system that uses a compact and energy-efficient compressor. The BLDC mini compressor is driven by an electric motor that uses direct current and doesn’t have the mechanical brushes that generate friction, heat, and wear in traditional AC (alternating current) motors. This results in improved energy efficiency, lower noise, and longer lifespan compared to traditional AC compressors

Technical Data

DC Micro Air Conditoner Model

12V DC MICRO AIR CONDITIONER

Model: DV1910E-AC (Pro)

- Voltage: 12V DC

- Cooling Capacity: 450W (1535Btu)

- Refrigerant: R134a

- Net Weight: 11.02 lbs / 5.0kgs

- Working current: 1~8A, (Max 10A)

- Size: 350*260*180mm (13.77*10.23*7.08 inch)

24V DC MICRO AIR CONDITIONER

Model: DV1920E-AC (Pro)

- Voltage: 24V DC

- Cooling Capacity: 450W (1535Btu)

- Refrigerant: R134a

- Net Weight: 11.02 lbs / 5.0kgs

- Working current: 1~7A, (Max 8.5A)

- Size: 350*260*180mm (13.77*10.23*7.08 inch)

48V DC MICRO AIR CONDITIONER

Model: DV1930E-AC (Pro)

- Voltage: 48V DC

- Cooling Capacity: 450W (1535Btu)

- Refrigerant: R134a

- Net Weight: 11.02 lbs / 5.0kgs

- Working current: 1~4A, (Max 7.5A)

- Size: 350*260*180mm (13.77*10.23*7.08 inch)

24V DC MICRO AIR CONDITIONER

Model: DV3220E-AC (Pro)

- Voltage: 24V DC

- Cooling Capacity: 550W (1876Btu)

- Refrigerant: R134a

- Net Weight: 12 lbs / 5.3kgs

- Working current: 1~10.3A, (Max 12.5A)

- Size: 350*260*180mm (13.77*10.23*7.08 inch)

Advantage

High Capacity

High Efficiency

High Reliability

Miniature Size

Low Weight

Low noise

Application

Features

High Performance By BLDC Motor

RIGID direct current mini compressor comes with a sine wave variable speed driver board, delivering efficient and reliable performance.

DC Inverter By RIGID Technology

Wide-range inverter compressors satisfy your innovative demands and design. Your product will stand out, your compressor will go unnoticed.

Smallest size and light weight

This ultra-compact solution meets the demands of thermal management systems that have limited installation space.

E-shop

Sample products are available from our online store. Your order will be proceeded in 24hrs and delivered by DHL/UPS/FedEx.

Micro Air Conditioner Projects

FAQs

1. Does this micro air conditioner unit run inside the space or does it need to be vented to outside of the cabinet?

There must be a heat emission hole in your system, you can use flexible tubes to connect the air conditioner unit.

2. How to connect the wiring diagram of RIGID mini cooling system?

All wires are ready before shipping. Users only need to do 3 steps:

1. Connect to the DC power supply

2. The drive board connects to the compressor

3. Connect to your system’s on&off switch

3. How does one recharge/refill the refrigerant?

All RIGID Aircon units are fully charged with oil and refrigerant before shipping. Users needn’t charge refrigerant. Afterwards, If you need to refill the compressor with refrigerant for maintenance, there’s one valve for a refrigerant refill.

4. Does your company make a controller device for the unit or do I need to wire up my own switches?

RIGID dc aircon module is a sub-system, without an On & Off switch, need to wire up your own switch. DC Aircon unit is filled with refrigerant and oil before shipping.

5. I’m not sure of is what to do with the two white wires on the driver board? Do I have to have a switch on these two wires for the compressor to run?

Two white wires need to be closed or wire up to your On/Off Switch. Wires merge is On, separate is Off

6. What’s the airflow of micro dc aircon unit?

The airflow is 27.8CFM.

7. How to deal with condensate water?

There is a drain for condensate water. You can collect the condensed water via a tube to a condensed collection tank (If you want to use the condensed water).

8. With the LED lights only the green one was twinkling the red one was not on.

The green one was twinkling, the red one was not on means that the motor is on standby, please merge the two white lines first.

9. How to control compressor speed?

There are 4 ways to adjust compressor speed.

1. Potentiometer speed control(already have)

2. 0-5v Speed control

3. PWM Speed Control

4. TTL communication port

The above 4 ways, the most common way to control the compressor is through potentiometer (included) adjustment.

10. The compressor is clicking on/off and does not get any colder than the ambient temperature?

1. Check if all wires are connected correctly.

2. Check DC power battery is fully engaged or not.

11. Does your aircon unit include refrigerant and thermostat?

RIGID DC Aircon unit, as well as other compact liquid chillers, have been fully charged with oil and refrigerant before shipping. About thermostats, you can purchase them in our online store.

12. How does it work for the payment and the shipping?

–PayPal, Credit cards, Bank transfer & L/C.

–DHL/UPS, By Air, By Sea are available.

–50% deposit in advance, balance against B/L or courier receipt.

13. What' the Warranty& maintenance

One-year warranty, lifelong technical support.

14. Can we return the aircon when the it has quality defects?

Yes, We will 100% refund you if the purchase has any quality defects!

15. RIGID Micro DC Aircon Working Principle

RIGID Micro Refrigeration Cooling System includes a miniature BLDC inverter compressor, driver board, condenser, evaporator, capillary and other refrigeration parts. The compressor is the heart of a cooling system, it uses a small amount of energy to generate the refrigerant flow and heat transfer as desired.

RIGID developed a miniature BLDC rotary compressor that efficiently generates a significant cooling capacity within a small volume. The compressor takes in low-pressure refrigerant vapour and compresses it to high pressure and temperature.

The refrigerant undergoes an isothermal phase change (gas to liquid) and rejects heat to the ambient environment at high pressure within the condenser.

The refrigerant throttled to low pressure and temperature (typically below ambient) through the expansion valve. Refrigerant enters the evaporator primarily as a liquid and again undergoes an isothermal phase change (this time from liquid to gas) as the evaporator absorbs heat from the environment.

The refrigerant again enters the compressor as a low-pressure vapour restarting the cycle.

The refrigeration cycle is demonstrated in the figure below.