FPSC Stirling Cooler – RIGID HVAC

FPSC-Free Piston Stirling Cooler (-160℃)

Medical field, Bio-science, Laboratory, semiconductor manufacturing, etc. Green power Stirling cryocooler brings us the cutting edge technology in ultra-low temperature applications.

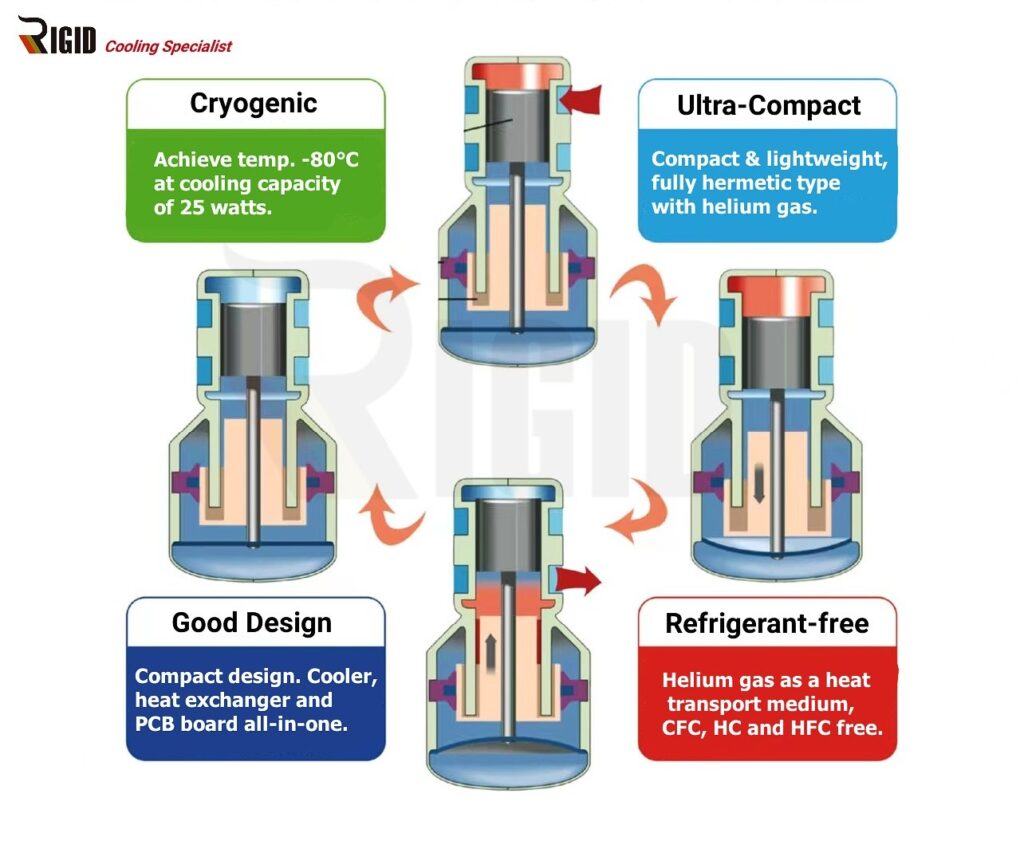

RIGID Stirling Cryocooler

This is the Stirling Cooler, which we refer to as the FPSC. We’ve prepared a product lineup of Stirling coolers that can cool to minutes 120℃ using helium gas as the refrigerant. Stirling cooler which differs from a compressor, is a cooling system that continuously repeats gas compression and adiabatic expansion and uses naturally occurring helium gas as the refrigerant. Helium is a very safe gas that is entirely harmless to our global environment. The typical use of Stirling Cooler is in refrigerators, but we are also developing a product lineup for us in laboratory equipment and in equipment used for low temperature distribution of goods.

The RIGID company FPSC is hermetically sealed in a stainless steel casing. The helium gas is repeatedly compressed and adiabatically expanded as two pistons reciprocate 80 time per second in one cylinder. As this occurs the tip or heating absorbing area is cooled when a heat exchanger is installed on this heat absorbing ares. The item targeted for cooling can be cooled, and the temperature of the heat absorbing area can be lowered from – 53 to- 120 in just few minutes.

FPSC Stirling Cryocooler-RIGID HVAC

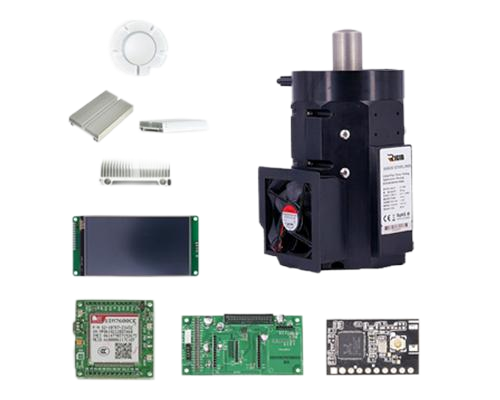

Stirling Cryocooler Models

A lineup of RIGID company Stirling cooler models include RS40 (40 watt), RS80 (80 watt) and RS100 (100 watt) models is available to meet a variety of application needs.

The standout feature of the RIGID Stirling Cooler lies in its ability to effortlessly create ultra-low temperatures of -100 degrees Celsius or even lower, a task often challenging for conventional compressor-type products. Astonishingly, it takes just 8 minutes to reach an impressive temperature of -120℃ after turning on the switch, showcasing its remarkable efficiency.

One of the striking advantages of the Stirling Cooler is its simplicity in design, resulting in a main body that weighs merely 1.7kg. This weight is only 1/5th of what conventional compressor cooling systems typically weigh, making it much more manageable and portable.

Free Piston Stirling Cryocooler

Notably, the Stirling Cryocooler is environmentally friendly, demonstrating its “environmental performance” through low power consumption and its utilization of helium gas as a refrigerant. This choice of refrigerant is especially important as it does not contribute to global warming, ensuring a more sustainable cooling solution.

Stirling Cryocooler Advantages

Free-piston Stirling cryocoolers have several advantages in medical laser and photonics applications:

- High Efficiency: They provide efficient cooling, ensuring device performance.

- Vibration-Free: Their operation is free from vibrations, crucial for precise optics.

- Compact and Lightweight: Ideal for portable and space-constrained systems.

- Long Maintenance Intervals: They are reliable with minimal downtime.

- Wide Temperature Range: Suitable for various temperature requirements.

- Environmentally Friendly: Use eco-friendly gas-Helium. No Freon, No CFC.

- Precision Control: Offer precise temperature control for accuracy.

- Reduced Costs: Lower operating and maintenance expenses.

- Low Noise: Produce minimal acoustic noise.

- Integration Flexibility: Can be customized for various applications.

FPSC Cryocooler Applications:

RIGID’s Stirling technology has gained popularity in the United States and Europe due to its versatility. It’s not just used in laboratories but has also proven valuable for safely transporting blood and vaccines. Furthermore, it’s found application in the United States and Japan for cooling frozen scalpels during cryoextraction procedures for warts and moles.

The RIGID Stirling Cooler stands out for its impressive cooling capabilities, efficiency, and environmentally friendly design. It uses helium gas as a refrigerant, which is safe for the environment and humans and does not contribute to global warming. It achieves extremely low temperatures, below minus 100 degrees Celsius, using the principle of adiabatic expansion. RIGID has achieved a significant milestone by successfully mass-producing this technology, marking the world’s first large-scale production of Stirling Coolers. This breakthrough opens up innovative possibilities for temperature-sensitive applications in various fields.

Stirling cryocoolers have a wide range of applications across various industries due to their efficient and reliable cooling capabilities. Some common applications of Stirling cryocoolers include:

- Military and Aerospace: Stirling cryocoolers are used for cooling infrared sensors, such as those found in night vision systems and missile guidance systems.

- Medical Laser Device: They are utilized in medical devices like MRI machines and medical laser systems, where precise and stable cooling is essential for accurate diagnostics and treatments.

- Scientific Research: Stirling cryocoolers are used in laboratories and research facilities for cooling superconducting materials, particle detectors, and low-temperature experiments.

- Space Exploration: In space missions, Stirling cryocoolers help maintain the temperature of scientific instruments, allowing for the study of celestial bodies and cosmic phenomena.

- Semiconductor Manufacturing: They are used for cooling components in semiconductor manufacturing equipment to maintain the integrity of microelectronics during production.

- Photonics and Optics: Stirling cryocoolers play a critical role in maintaining the stability and performance of laser systems and high-resolution optical instruments.

- Cryopreservation: They are employed in the preservation of biological samples, such as sperm, eggs, and tissues, for use in fertility treatments and medical research.

- Environmental Monitoring: Stirling cryocoolers can be used in sensors and detectors for environmental monitoring, including gas sensing and pollution control.

- Telecommunications: They are used in cooling components of high-speed data transmission equipment, ensuring the reliability and efficiency of communication systems.

- Electronics Cooling: Stirling cryocoolers can be used for cooling electronics in applications where traditional cooling methods are inadequate.

- Energy Storage: In some experimental energy storage systems, Stirling cryocoolers are used to store energy in the form of cryogenic fluids for later use.

- Cryosurgery: They are utilized in cryopreservation and cryosurgical applications, where extreme cold is used to treat various medical conditions, including cancerous tumors.

- Food Processing: In the food industry, Stirling cryocoolers are used for rapid freezing and cooling of food products.

These applications showcase the versatility of Stirling cryocoolers in providing reliable and precise cooling across a wide range of industries and technologies. Their efficiency, low vibration, and long maintenance intervals make them an attractive choice for many cooling requirements.

Get A Sample Online

Beyond its impressive cooling capabilities, the Stirling Cooler offers additional advantages. It boasts a lightweight, compact, and portable design, making it easy to transport and use in various settings. Additionally, the cooler significantly reduces power consumption, contributing to energy efficiency.

As a result, this innovative technology is anticipated to find applications in diverse fields, including outdoor cooler boxes, medicine, and semiconductor manufacturing. With its outstanding cooling performance and versatile features, the Stirling Cooler opens up new possibilities for advanced cooling solutions in a wide range of industries.

For example, there are many machines and devices that are partially cooled to improve accuracy, such as MRI (Magnetic Resonance Imaging), and the manufacturing process of semiconductors and liquid crystals requires cryogenic temperatures to increase the degree of vacuum. FPSC is perfect for such needs of ‘making a limited space like a cooler box extremely cold in a short period of time.

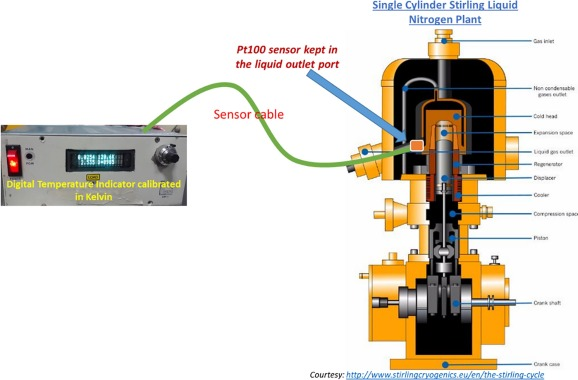

FPSC Working Principle

FPSC – Stirling Cooler Working Principle

RS100 Working Video

Summarize

RIGID company Stirling coolers represent the prevalent modern application of the Stirling cycle. In a typical Stirling engine, external heat is applied to a cylinder, and the expansion and compression of air or gas inside the engine drive a power piston. A lightweight “displacer” piston precedes the power piston, shuttling the air or gas between the hot and cold ends of the cylinder.

However, in a Stirling cooler, the cycle operates in reverse. An external power source, like an electric motor, compels the power piston to move ahead of the displacer. This reversal leads to gas compression and expansion within the cylinder, without any phase changes or liquid refrigerants involved.

Modern “free piston” Stirling coolers, like the one demonstrated in the video, use helium pressurized at approximately 400 psi and operate at a rate of about 60 cycles per second. These free piston Stirling engines/coolers were invented by William Beale of Ohio in the 1960s and are designed to operate at exceptionally high speeds without the need for linkages, lubrication, or frequent maintenance.

The specific 100-watt Stirling cooler – model RS100, showcased in the picture is a product of the RIGID company. These Stirling coolers are increasingly finding applications in various fields, including medicine, laboratory research, space exploration, defense, and scientific investigations. Their reliable and efficient cooling capabilities make them highly valuable assets in modern technology and research advancements.