A mini compressor is a refrigeration compressor with a cooling capacity of less than 1KW, with mini size, lightweight and super durability; quiet work, almost no vibration; very low energy consumption, can use a battery, vehicle power, civil grid, solar power supply; with stable output, accurate control, and superior adaptability, can well meet the requirements of all kinds of a mobile and portable microthermal management system.

It is known compressor is the core of the refrigeration system. Its capability and characteristics determine the capability and characteristics of the refrigeration system. RIGID mini dc rotary compressors, with small size, lightweight, high power, low energy consumption, quiet and vibration-free operation. It is the variable frequency and easy and precise control.

Miniature compressors can be said to be tailor-made for cutting-edge refrigeration systems and are also extremely ideal for mobile or portable miniature thermal management systems. Miniature compressors can be widely used in air conditioning units, water cooling units, commercial refrigeration units, and their main applications include portable refrigeration systems, food cooling systems, miniature refrigeration systems, temperature-controlled shipping containers, electronic refrigeration systems, medical imaging systems, mini cooling water systems, etc.

Here are pictures from our client – Mr. MICHAEL ST. PIERRE (an inventor, engineer, and scientist all rolled into one) fully testifies RIGID 12v miniature compressor’s power and stability. Michael even removed the insulation from the evaporator coil while the 12V compressor was still running, and only lost 10 degrees, while increasing the dc compressor amperage by almost 1 amp (just under 6 amps). From the article below, you can see RIGID miniature dc compressor is pretty strong!

What’s Inside A Mini BLDC Rotary Refrigeration Compressor?

RIGID Miniature Compressor – Advantage

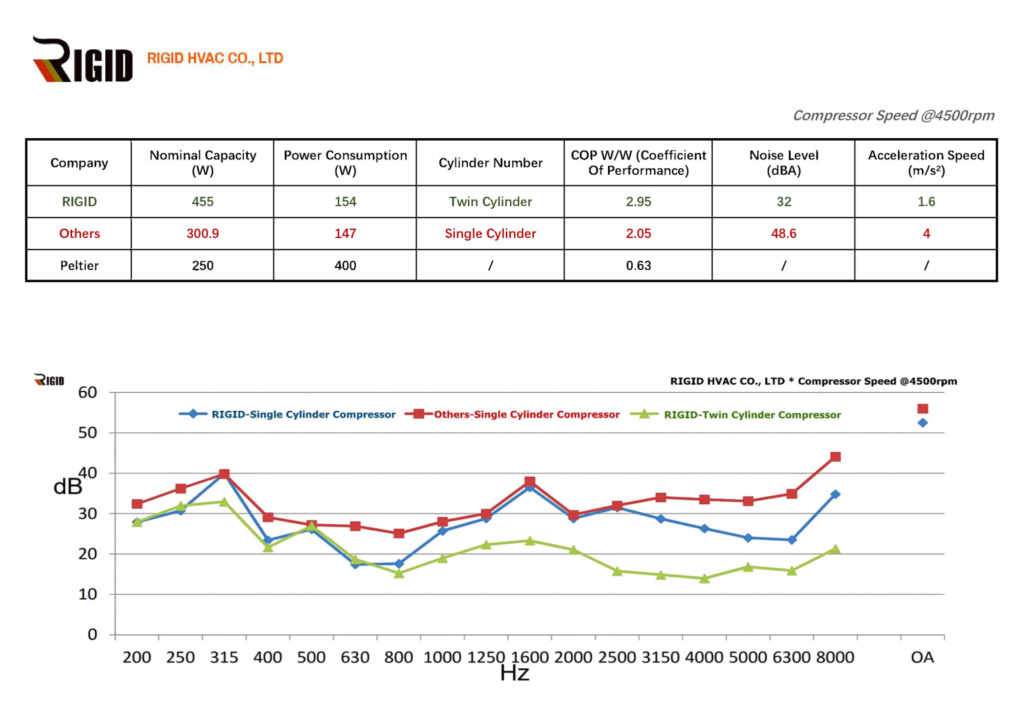

Smooth Operation: In the micro compressor, for a certain working chamber, the suction, compression, and elimination of the gas mass is completed within two weeks of the eccentric wheel shaft rotation, but because the rolling piston and the slide plate form the working chamber on the left and right sides, the suction, compression and discharge process is carried out simultaneously, then for the whole compressor, the eccentric wheel shaft still completes an effective working cycle in each rotation, which can make the operation smooth.

Higher efficiency: In the micro compressor, the process of suction, compression, and discharge is carried out simultaneously in the working chamber on both sides of the slide, no suction valve and no additional suction and discharge muffler are needed, which reduces the flow resistance loss in the process of suction and discharge, and the indicated efficiency is generally 30%-40% higher than that of reciprocating piston compressor.

Compact structure: the micro compressor is a cylindrical cylinder and rolling piston for rotary motion with each other and direct rotary compression, no need to convert the rotary motion into reciprocating motion of the motion conversion mechanism, its parts are less, especially the perishable.

Simplicity: Less parts, simple structure, small volume, lightweight, 1/3 less than the general reciprocating piston compressor parts, 40%-50% smaller volume, about half the weight.

Brushless Motor Drive: Micro compressor by brushless DC motor as the prime mover, brushless DC motor has a fast response, large starting torque, from zero speed to rated speed with the performance of rated torque, easy to achieve variable speed frequency control of micro compressor, and can use batteries, vehicle power, civil power grid, solar power, etc., to enhance the adaptability of the system.

The mini dc compressor is the core of the refrigeration system and its capacity and characteristics determine the capacity and characteristics of the refrigeration system. With small size, lightweight, high power, low energy consumption, quiet and vibration-free operation, variable frequency, and easy and precise control, miniature compressors can be said to be tailor-made for cutting-edge refrigeration systems and are also extremely ideal for mobile or portable small thermal management systems.

RIGID Miniature compressors can be widely used in air conditioning units, water cooling units, and commercial refrigeration units, and their main applications include portable refrigeration systems, food cooling systems, miniature refrigeration systems, temperature-controlled shipping containers, electronic refrigeration systems, medical imaging systems, mini cooling water systems, etc.

RIGID miniature bldc rotary compressor, which is the world’s smallest refrigeration compressor.

RIGID Mini Compressor – Parameters

- Models: QX19 series & QX32

- Refrigerant: R-134a.

- Motor: Brushless motor.

- Oil type: POE RL 68H.

- Discharge capacity: 1.9 cc & 3.5cc

- Weight: 720g.

- Size: 56mm (diameter) X 89.7mm (height).

- Current: 1A – 12A.

- Maximum current: 9.5A (normal is 5A).

- Voltage: 12V / 24V / 48V

- Evaporation temperature: -18°C ~ 24°C.

- Condensing temperature: 27°C ~ 71°C.

- Applicable ambient temperature:-30°C ~ 60°C.

- Maximum withstand temperature: 130°C.

- Rotational speed: 2000 ~ 6500rpm