Introduction – Laser Liquid Chiller

Laser technology has revolutionized various industries, from manufacturing to medical procedures. However, the efficient operation of lasers heavily relies on managing the heat they generate. This is where innovative cooling solutions like liquid chillers step in, ensuring optimal performance and longevity for your laser equipment.

Laser devices produce a significant amount of heat during operation due to the energy conversion processes involved in generating laser light. This heat buildup can compromise performance, efficiency, and even the lifespan of your laser equipment. This is why effective cooling mechanisms are crucial.

Laser technology has revolutionized various industries, from manufacturing to medical procedures. However, the efficient operation of lasers heavily relies on managing the heat they generate. This is where innovative cooling solutions like liquid chillers step in, ensuring optimal performance and longevity for your laser equipment.

Laser devices produce a significant amount of heat during operation due to the energy conversion processes involved in generating laser light. This heat buildup can compromise performance, efficiency, and even the lifespan of your laser equipment. This is why effective cooling mechanisms are crucial.

Laser Liquid chiller

What Are the Best Liquid Cooling For Lasers?

The answer is, Vapor Compressor Liquid Cooling!

Closed-Loop Liquid Cooling Systems: These systems use a closed-loop setup with a pump, radiator, and coolant to efficiently dissipate heat from the laser components. They are relatively easy to install and maintain.

Chiller Units: Chiller units are widely used for cooling lasers. They offer precise temperature control and can handle high heat loads. They use a refrigeration cycle to remove heat from the coolant and maintain a stable temperature.

RIGID Company’s Compact Liquid Chillers

For those seeking cutting-edge liquid cooling solutions, RIGID Company offers a range of compact liquid chillers specifically designed for laser systems. These advanced chillers ensure precise temperature control and efficient heat dissipation, even in space-limited environments. RIGID Company’s liquid chillers are engineered to provide the optimal cooling performance required for demanding laser applications.

Furthermore, RIGID company also provides customizable cooling profiles. One of the standout features of liquid chillers is their adaptability. You have the freedom to customize cooling profiles to match your laser’s unique cooling requirements. This level of customization ensures that the cooling process is tailored precisely to the needs of your laser equipment, optimizing its performance and efficiency.

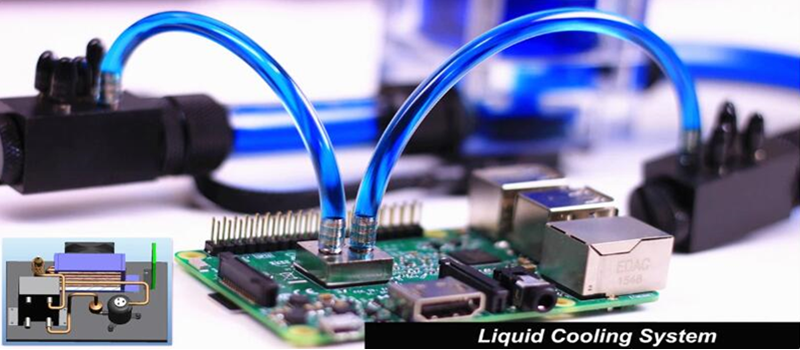

It is known that RIGID company liquid cooling system has emerged as a key solution for managing heat in laser systems. By utilizing a miniature BLDC compressor liquid chiller, you can actively control the temperature of your laser equipment, ensuring that it operates within its optimal temperature range. This precise temperature control is essential for maintaining consistent performance, stability, and output characteristics.

RIGID compact dc cooling system is an effective approach in liquid cooling for lasers is the active water cooling method. This method employs a liquid chiller system that circulates temperature-controlled water around the laser components, efficiently dissipating heat and maintaining a stable temperature. Active water cooling provides superior heat transfer capabilities compared to traditional air cooling methods, making it particularly suitable for high-energy lasers that produce substantial heat loads.

Longevity and Reliability of Laser Chillers

The benefits of employing liquid chillers extend beyond immediate temperature control. By preventing overheating and maintaining a stable operating environment, these cooling solutions contribute to the longevity and reliability of your laser equipment. This means fewer maintenance headaches and greater cost savings in the long run.

Why Laser and Photonics Systems Need Cooling?

Laser and photonics systems generate significant amounts of heat during operation due to the energy conversion processes involved in producing laser light or manipulating photons. This heat can adversely affect the performance, efficiency, and lifespan of these systems.

Advantages of RIGID Liquid Chillers in Laser and Photonics Systems?

- Maintain Laser Excellence: Liquid chillers uphold the ideal temperature, securing steady and dependable performance.

- Stay Calm under Heat: These chillers promptly dispel surplus heat, averting overheating and ensuring a secure operational environment.

- Customized Cooling Solutions: You’re in charge – adapt chiller settings to precisely match your laser’s distinct cooling prerequisites.

- Bidding Adieu to Heat Concerns: Liquid chillers excel at diffusing heat, especially advantageous for lasers producing high energy.

- Serene Operation: Liquid chillers operate seamlessly and silently, contributing to a more tranquil workspace.

- Space-Friendly Fit: Designed for efficiency, liquid chillers neatly integrate into your available space.

- Prolonged Longevity: Halt overheating, extending your laser’s lifespan through effective cooling measures.

- Consistent Outcomes Every Time: Controlled temperatures lead to reliable and steady laser performance.

- Adaptability for All Lasers: Liquid chillers handle various laser types, even those that generate substantial heat.

- Centralized Cooling Approach: Streamline management with one chiller for multiple lasers, creating an organized cooling network.

In a nutshell, liquid chillers offer an array of advantages for your laser equipment. They ensure performance, longevity, and safety across various applications, whether it’s for research or industrial use.

Get A Sample Chiller Online

Conclusion:

RIGID, renowned for its leadership in micro refrigeration, has extended its expertise to encompass an array of liquid cooling chillers and modules, built upon its proprietary mini compressors. These advanced offerings are tailored to address the specific requirements of customers seeking to incorporate micro refrigeration modules and solutions within their equipment.

At the forefront of RIGID’s lineup are the Compact Liquid Chillers, meticulously designed to furnish essential cooling capabilities for applications that demand portability and compactness. Comprising four key components – Compressor, Condenser, Capillary or Expansion Valve, and Evaporator – these compact chillers embody efficiency and reliability.

Furthermore, the RIGID Liquid Chiller sets itself apart by incorporating a dedicated drive board. This strategic integration facilitates seamless packaging and interconnection of refrigeration circuits, thereby enhancing operational convenience for clients.

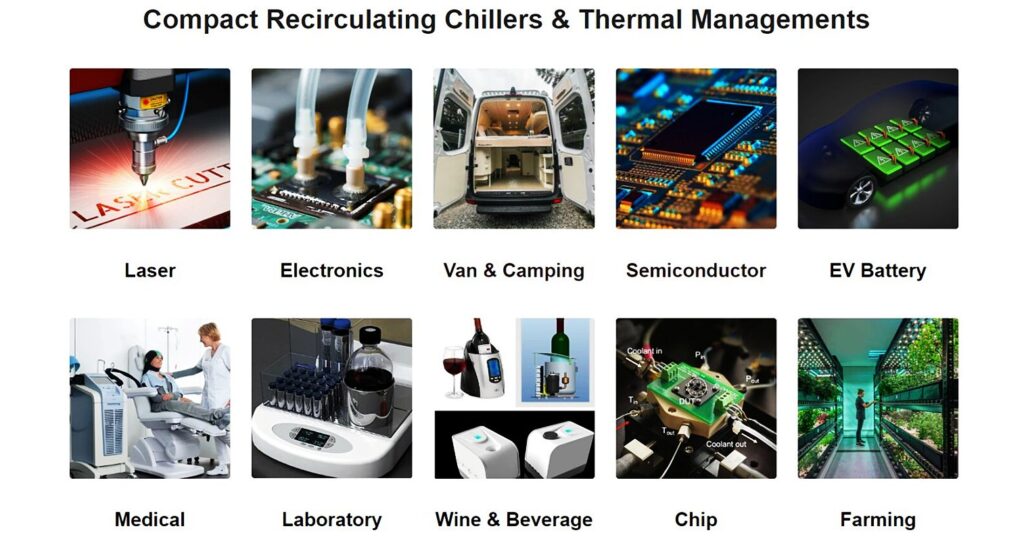

The applications of RIGID’s Compact Liquid Chiller (LCM) have traversed diverse industries, making notable contributions to Medical & Aesthetic, Drone Technology, Life Sciences, Vertical Farming, Laboratory Instruments, Electronic Cooling, Laser Cooling, and personal cooling domains.

RIGID’s dedication to innovation and precision positions it as a prominent figure in the realm of liquid cooling solutions, backed by a legacy of micro refrigeration excellence.