- Project: Custom HVAC cooling system for aesthetics and medical lasers.

- Cooling Approach: Recirculating water-cooled

- Demand: An American company that specializes in the Aesthetic and medical laser market, is looking for a Direct Expansion System with a cooling power of ~900W for a new Medical Laser device. This small refrigeration system is integrated into a laser device intended to cool down the initial temperature 50℃ to 2 degrees Celsius in minutes.

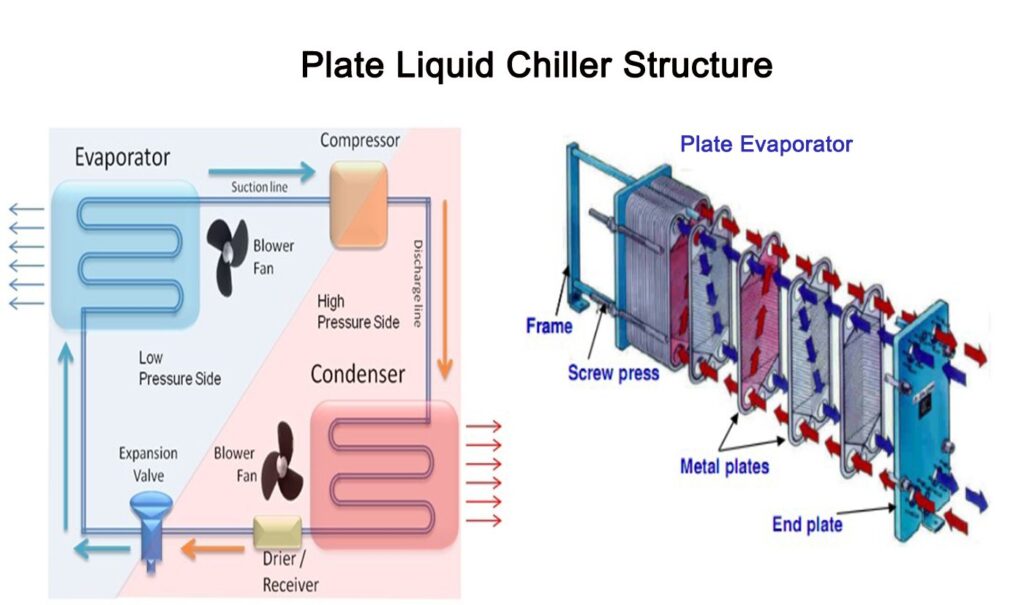

- Recommended product: Plate Liquid Chiller

Unlocking Thermal Management Benefits: The Compact Cooling of Medical Lasers

Plate Liquid Chiller-RIGID

Get A Sample

———————————

Background

Lasers offer various health benefits, especially in the medical field. They are used in a wide range of applications, from surgery to regenerative and aesthetic medicine. Different types of lasers are employed for specific purposes based on their wavelengths, radiation duration, and power. The versatility of lasers allows them to transform light energy into mechanical, thermal, or chemical energy, making them valuable tools in medicine. They are particularly useful in less invasive treatment procedures for various medical conditions.

The RIGID company focuses on miniature cooling, using mini DC compressor technology for medical diode laser cooling for minimally invasive applications across numerous medical specialties. These lasers find applications in general and cosmetic surgery devices and equipment, offering innovative and effective solutions in the medical field.

RIGID Small Chiller Functions

RIGID Integrated water chillers are vital components within aesthetic and medical laser devices, serving essential functions. They regulate the laser’s temperature, ensuring it operates safely and effectively, thereby guaranteeing patient safety and maintaining consistent laser output. Moreover, these chillers enhance precision by preventing temperature fluctuations, extend the device’s lifespan by reducing stress on internal components, and enable consistent performance crucial for treatment efficacy.

Additionally, they contribute to patient comfort and safety by keeping laser handpieces cool and preventing discomfort and burns during procedures. In summary, integrated water chillers are indispensable in laser-based medical and cosmetic treatments, ensuring precision, reliability, and patient well-being.

Integrated water chillers are essential components in aesthetic and medical laser devices. They serve several vital functions:

- Temperature Control: Water chillers regulate the laser’s temperature to maintain safe and effective operating conditions, ensuring patient safety and consistent laser output.

- Enhanced Precision: They prevent temperature fluctuations, preserving the laser’s accuracy for precise medical and cosmetic procedures.

- Prolonged Device Lifespan: By dissipating heat and reducing stress on internal components, water chillers extend the lifespan of laser devices.

- Consistent Performance: They enable lasers to operate at a constant temperature, ensuring stable and reliable performance critical for treatment efficacy.

- Patient Comfort and Safety: Water chillers keep laser handpieces cool, preventing patient discomfort and burns during treatments.

In summary, integrated water chillers are indispensable components within aesthetic and medical laser devices. Their ability to control temperature, enhance precision, extend device lifespan, ensure consistent performance, and prioritize patient comfort and safety underscores their critical role in the success of laser-based treatments. These devices are a testament to the meticulous engineering and innovation that drive advancements in the medical and cosmetic fields.

RIGID direct current cooling systems are well-integrated water chillers to the success of laser-based medical and cosmetic procedures, safeguarding precision, reliability, and patient well-being.

Plate Liquid Chiller -12V/24V/48V

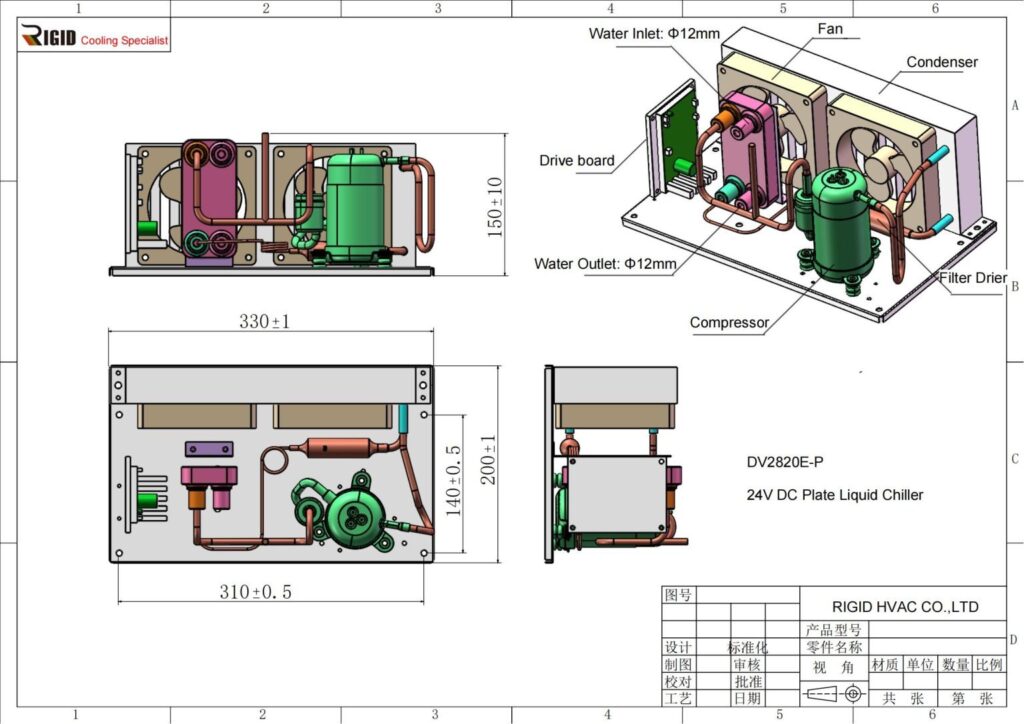

Plate Liquid Chiller, DV2820E-P R134a drawing

Solution: DC Chiller DV2820E-P(T)

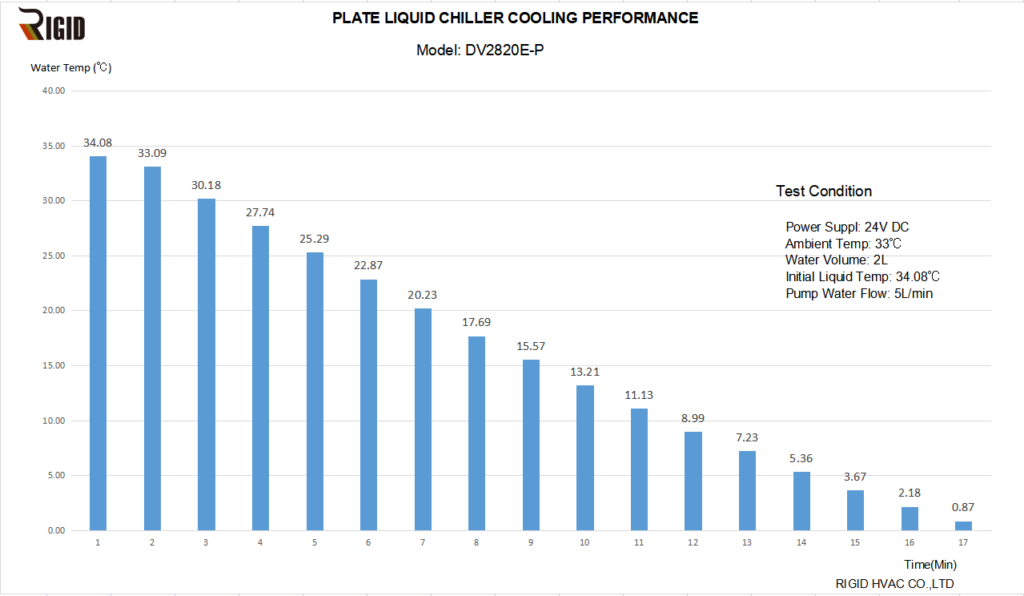

The 24V Recirculating Water Chiller DV2820E-P (T) adopts environmental refrigerant R290. It is a promising solution for your cooling requirements. It utilizes an aluminum heat dissipator with circulating water to effectively dissipate heat from your electronics. Here are some key features and specifications:

- Cooling Power: The chiller provides the necessary cooling power of 500W to match heat generation.

- Flow Rate: A flow rate of 2 liters per minute is sufficient to maintain the desired temperature.

- Temperature Control: While the standard chiller does not include temperature control, it offers the flexibility to add a thermostat if needed. This allows you to precisely regulate and maintain the temperature of the circulating water.

Efficiency and Speed

The attached chart shows that it takes only 16 minutes to cool 2 liters of water to the target temperature of 2°C from an initial temperature of 34°C.

Customer Comments

“Our primary obstacle centered on cooling the diodes. When we’re working with laser diodes producing 1kW of optical output, we must dissipate around 500 Watts of heat to maintain a diode temperature of 25 degrees Celsius. Traditional standalone laser chillers, which are three times the size of our enclosure, were quickly ruled out,” noted Michael.

We explored Thermal Electric Cooling (TEC) as an alternative but soon encountered significant limitations. The size remained too bulky to integrate into our enclosure, and the efficiency left much to be desired. TECs generated over 1 kW of heat, which needed to be expelled into the room. To mitigate this, we had to install large fans, but they proved too noisy for use in a clinical setting.

“RIGID’s compact chiller systems have proven to be the perfect fit for our needs – compact size, lightweight, high efficiency, and noiseless operation,” Michael affirmed. “The inclusion of RIGID’s small refrigeration unit has played a pivotal role in our success. Thanks to the RIGID chiller, we can now proudly offer our Hpc (High Power Cooling) technology, which has become a reality.”

DC Inverter Chiller Applications

Electronic components generate heat during operation, and if not properly managed, this excess heat can lead to performance issues and even damage. In your case, you are dealing with electronics that produce 16W of heat power. To maintain them at a safe operating temperature, you need an efficient cooling system.

Unlocking Peak Performance within a Compact Design

The key to its impressive compactness lies in the innovative HPC High Power Cooling technology. This cutting-edge system harnesses the capabilities of a next-generation chiller, leaving behind the bulky constraints of previous technologies.

It excels at rapidly dissipating the substantial heat generated by high-powered diodes. Through meticulous performance-oriented design, power seamlessly transforms into a driving force for reducing dimensions.

Custom Cooling Solution For Medical Lasers

As your project is associated with a medical device company and you are based in Spain, regulatory compliance is vital. The Recirculating Chiller QD25H110 does not mention specific certifications like the CE mark or UL in the provided information. Therefore, it is crucial to reach out to the manufacturer or supplier to confirm if it meets the required regulatory standards for your medical device application.

Custom Recirculating Chiller

Conclusion

In the field of medical aesthetics, maintaining precise temperature control in laser equipment is paramount to enhancing overall performance and durability. With a 13-year specialization in micro cooling, RIGID introduces a game-changing solution through its DC variable frequency chiller.

This innovative system offers efficient cooling capacity, rapid temperature management, and the flexibility to seamlessly integrate a thermostat into the user’s equipment, enabling precise and reliable temperature regulation.

About RIGID

At RIGID HVAC, we’re not just a company; we’re an avant-garde engineering and manufacturing powerhouse specializing in compact cooling systems and efficient thermal management solutions.

Our Expertise and Offerings:

- Complete Cooling Solutions: We excel in everything from cooling individual electronics to optimizing entire systems.

- Innovative Mechanical Packaging: Our creative minds are at your service for the most efficient and compact packaging designs.

- Tailored Design Services: We craft custom solutions that precisely match your unique needs.

- Air and Liquid Cooling Expertise: Our mastery extends to both air and liquid cooling systems.

- Swift Prototyping: We turn ideas into reality at lightning speed with our rapid prototyping capabilities.

- Bespoke Heat Sink Design: Your thermal needs are unique, and so are our custom heat sink designs.

- Engineering Excellence: Elevate your team’s skills with our comprehensive engineering training programs.

- Cutting-Edge Thermal Instruments: Explore the realm of research-grade thermal instruments with us.

At RIGID HVAC, we’re not just cooling; we’re revolutionizing the way you think about thermal management.

Compact Liquid Chiller – RIGID HVAC