- Project: Water Cooling System (Heat & Cool)

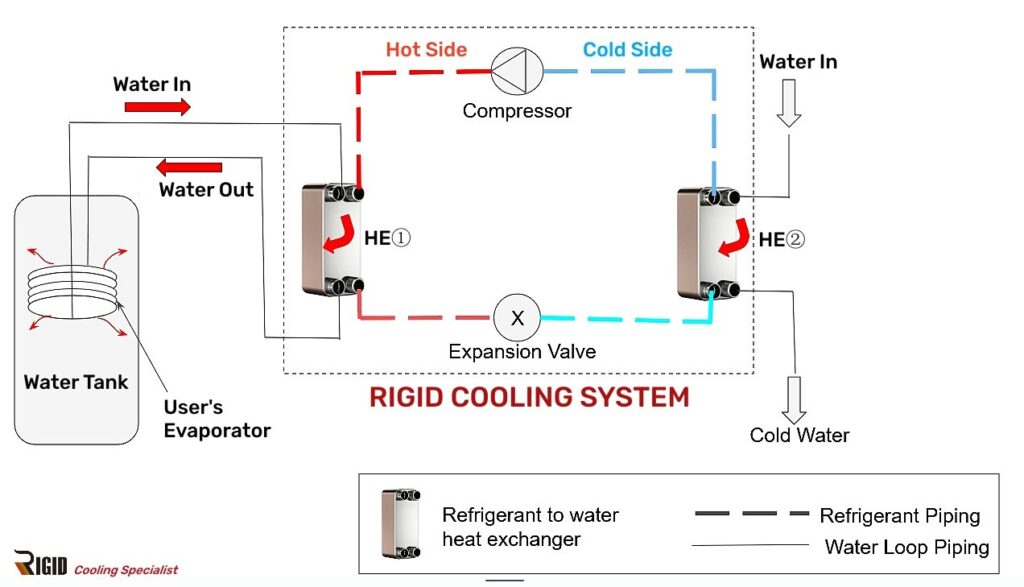

- Cooling Approach: Recirculated Water-cool

- Demand: The customer is seeking a compressor heat pump system for a small hot water heater and condenser. He needs a continuous supply of 500-700W worth of heat in the form of hot water at a temperature of at least 65C or hotter. The evaporator coils need to be made from stainless steel or other corrosion-resistant material.

- Recommended product: Tailor-made compressor cooling system.

Contact Us for Design

Background:

The customer is seeking a specialized heat pump system with specific heating, cooling, and custom design requirements. They require a compact hot water heater and condenser (500-100W), delivering a continuous 500-700W of hot water at 65C or higher. The evaporator coils must be corrosion-resistant. Additionally, the system should condense water vapor from a 60C hot air stream. The customer is interested in custom heat pumps for temperatures above 60C and condenser coils wrapping around a stainless steel container.

There’s been a recent shift in design, focusing on heating and cooling water streams rather than stainless steel requirements for the evaporator. NPT pipe ports are needed for integration with an existing water system. The heat pump must add 700W to raise the water temperature from 60C to 65C and simultaneously remove 700W from a 15C water stream on the cooling side. Both hot and cold water loops should maintain constant flow rates with stable temperatures. Notably, achieving a minimum outlet temperature of 64C in the hot water loop is a critical detail. The customer is currently in the exploration phase to determine the feasibility of constructing a heat pump that meets these specifications.

closed recirculating cooling water system-RIGID HVAC

Key Points:

1- Heating Requirements:

- Small hot water heater and condenser (500-100W).

- Continuous supply of 500-700W heat in hot water (65C or hotter).

- Evaporator coils are made of corrosion-resistant material.

2- Condensation of Water Vapor:

- Condensing water vapor from hot air (60C) using the heat pump’s evaporator.

3- Custom Design Considerations:

- Inquiry about designing custom heat pumps for temperatures above 60C.

Interest in custom condenser coils around a stainless steel container.

4- Change in Design:

- Shifted to heating and cooling water streams.

- No longer requires stainless steel for the evaporator but needs water heating and cooling.

- NPT pipe ports are needed for connection to an existing water system.

5- Specific Heat Pump Operation:

- Heat pump to add 700W to raise water temperature from 60C to 65C.

- The same heat pump to remove 700W from water at 15C on the cooling side.

6-Water Flow Details:

- Constant flow rates and stable temperatures in hot and cold water loops.

- Hot water loop: Flow rate 3 LPM, in at 60C, minimum outlet 64C.

- Cold water loop: Flow rate 3 LPM, in at 10-20C.

Solution:

After studying the customer’s application and requirements, the RIGID R&D team decided to tailor-made a compressor heat pump system for the customer’s specifications. The cooling system involves several key components and considerations. Below is a general guide outlining the major steps in designing such a system:

1. System Components:

a. Miniature BLDC Compressor:

Choose a micro DC compressor suitable for the required heating and cooling capacities.

b. Heat Exchangers:

Design separate water-cooled heat exchangers for the hot and cold streams. Ensure one can operate as a condenser (hot side) and the other as an evaporator (cold side).

c. Refrigerant:

Select natural refrigerant R290 that meets the efficiency and temperature requirements. Consider environmentally friendly options.

d. Expansion Valve or Capillary:

To regulate refrigerant flow and control the temperature.

e. Pump:

Integrate a tiny pump to ensure a constant flow rate in both hot and cold water loops.

f. Control System:

Implement a miniature compressor’s drive board that connects to the customer’s control system to monitor and adjust the heat pump’s operation based on temperature requirements.

2. Hot Water Loop:

a. Hot Water Heater:

The hot water heater should receive heat from the condenser. Design it to raise the water temperature from 60C to at least 65C.

b. Heat Exchanger:

Incorporate a heat exchanger to transfer heat from the refrigerant (hot side) to the hot water loop.

c. Flow Control:

Adjust flow rates to accommodate the heat pump heat exchanger if needed.

3. Cold Water Loop:

a. Evaporator:

The evaporator should extract heat from the cold water loop, lowering the temperature from the inlet to the desired 15C.

b. Heat Exchanger:

Use a heat exchanger to transfer heat from the refrigerant (cold side) to the cold water loop.

c. Flow Control:

Adjust flow rates in the cold water loop as needed.

4. Custom Design Considerations:

a. Materials:

Ensure that materials for heat exchanger coils are corrosion-resistant, considering the change in design regarding stainless steel.

b. Container Integration:

If required, design custom condenser coils to wrap around the outside of a stainless steel container.

5. Control Strategy:

a. Temperature Control:

Implement a control strategy to maintain stable temperatures in both hot and cold water loops.

b. Energy Transfer:

Program the heat pump to add 700W of energy to the hot water loop and remove 700W from the cold water loop.

6. Testing and Adjustment:

Conduct thorough testing to ensure the system meets temperature and flow rate requirements. Make adjustments as needed to optimize performance.

Considering energy efficiency and the potential for future improvements, The RIGID R&D team’s custom compressor water cooling system complies with safety and environmental regulations.

It’s important to note that specific details of the design may vary based on the chosen components, system size, and other factors. If you are seeking a compact water cooling system, do not hesitate to contact us. Our nice mechanical engineers are happy to reply to you in 12hrs. Our professionals in HVAC systems can provide more detailed and tailored guidance for your specific project.

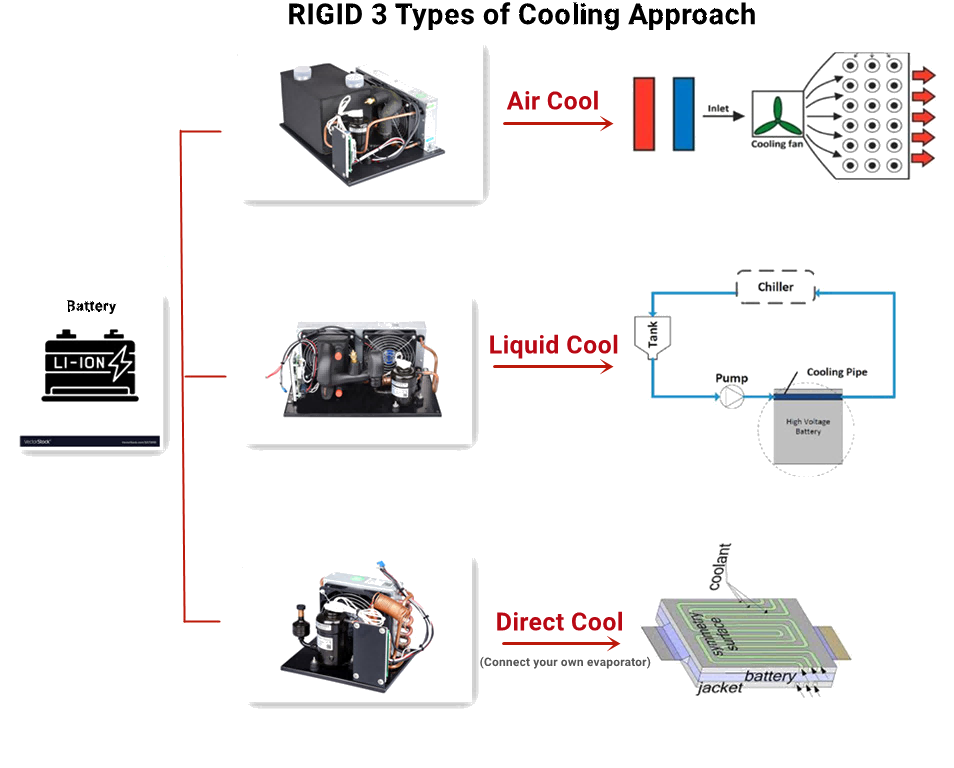

More Cooling Solutions:

RIGID Technology offers customized and off-the-shelf cooling systems that deliver full-size thermal management.

At RIGID, we take pride in quickly creating small cooling technologies and offering personalized service. Our range includes small cooling systems and patented miniature compressors that can fit almost any use.

We’re happy to design a custom solution to meet your specific needs. Just tell us what you’re looking for, and we’ll collaborate with you closely. We’ll create a design, develop a drawing, provide a prototype, assist with validation, and manufacture products that precisely meet your requirements. Whether you’re looking for new technology, product updates, or starting a new project, our dedicated engineers are here to support you and help you succeed.

Contact us today to learn more about our compact cooling solutions. We’re ready to assist you in making more progress with your projects.