- Project: To Collect Water from the Air

- Cooling Approach: Compressor Condensing System

- Demand: A Holland company specializing in providing drinking water solutions for challenging environments, seeks a cooling system for their technologies. The system should have a 450-500 W capacity at a 2°C evaporation temperature, preferably a 24V version. Its purpose is to condense 50 kg of steam at 30°C ambient temperature, with the desired outflowing water temperature as close to 30°C as possible.

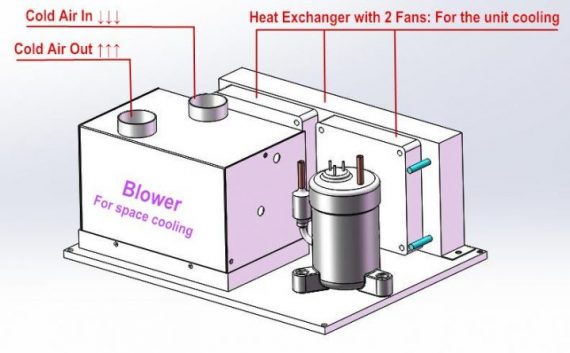

- Recommended product: Micro DC Aircon DV3220E-AC

Get A Sample Online

Background

The Holland company has been committed to providing safe drinking water in challenging environments since 2016. The focus on manufacturing and research in Rotterdam, along with the dedication of your engineering and sales teams, speaks to a holistic approach to addressing water scarcity.

The emphasis on sustainability is commendable, particularly with the utilization of Air-to-Water and Water-to-Water technologies. The fact that these units can be powered by renewable energy sources such as wind or solar power aligns well with the growing global interest in environmentally friendly solutions. The flexibility to connect these units to the grid or a generator adds versatility, ensuring adaptability to various conditions.

The company uses RIGID company’s Micro DC Aircon for water collection and extracts moisture from ambient air through a cooling process, causing condensation. This condensed water is then collected and purified, providing a sustainable source of safe drinking water. The system, often powered by renewable energy, employs a capacity controller for efficiency and adaptability, contributing to the company’s commitment to making safe drinking water accessible in challenging environments.

Solution

RIGID HVAC customized a compressor cooling system for the project. To meet the specified requirements, here’s a breakdown of the key points:

- Compressor Condensing Cooling System Design:

Ensure that the new cooling system is designed to accommodate the changes in the project’s specifications.

- Cooling Capacity and Temperature Requirements:

Aim for a cooling system with a capacity of 450-500 W at a 2°C evaporation temperature, recommended model DV3220E-AC (24V)

- Condensing Steam:

The cooling system should be capable of condensing 50 kg of steam at 30°C ambient temperature. Ensure that the outflowing water is as close to 30°C as possible.

- Voltage Preference:

Provide a 24V version of the cooling system, as per the preference.

- Capacity Controller:

Include a capacity controller in the design to enable adjustment of cooling capacity based on steam availability.

When customizing the system, RIGID engineers also consider the efficiency, reliability, and environmental impact. Additionally, they communicate with the Holland engineering team throughout the design and implementation process. We do everything to ensure the customized cooling system aligns with the client’s specific project needs.

RIGID cooling system to collect water from the air

Case Study

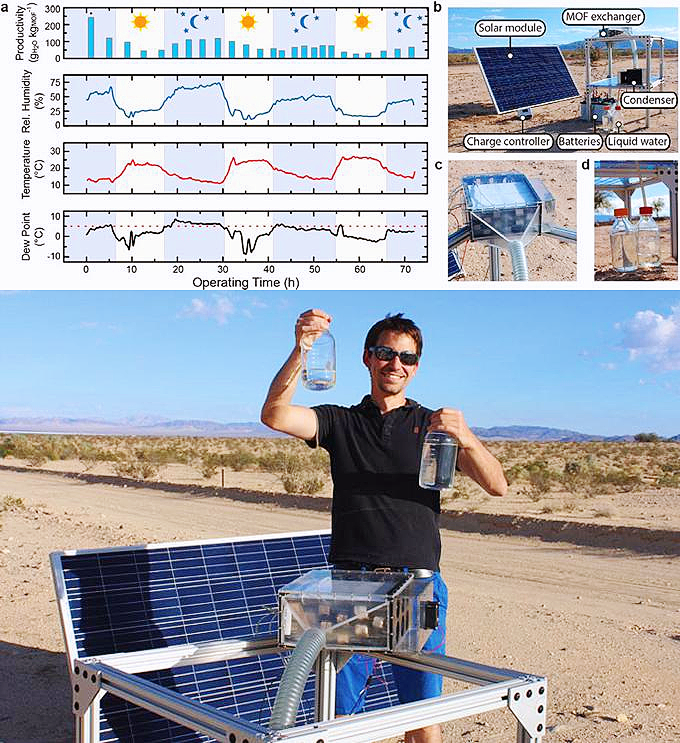

This is another case in which choose RIGID company product model DV3220E-AC. It has developed a water harvesting technology using Metal-Organic Frameworks (MOFs) with exceptionally large internal surface areas.

Background

A groundbreaking water-harvesting material developed at the University of California, Berkeley, holds immense promise for providing water in dry and off-grid areas globally. Created by chemistry professor Omar Yaghi and his team, the material, known as a metal-organic framework (MOF), exhibits extraordinary porosity, with 1g having a surface area equivalent to a football field. In testing at California’s Mojave Desert, the MOF-based water-harvesting device produced approximately 0.7 liters of water per kilogram per day, even in extremely low humidity conditions (7%).

Unlike traditional methods requiring cooling, this technology operates at low humidity without such constraints. The MOF-303 variant used in the latest project demonstrated a 30% increase in water-holding capacity compared to previous versions. The microwave-sized device, powered by solar panels, employs fans and heaters to facilitate the absorption and release of water within the MOF.

Yaghi’s startup, Water Harvesting Inc., is exploring devices capable of supplying 7-10 liters of water daily, with future aspirations for a refrigerator-sized unit producing 200-250 liters and village-scale harvesters yielding up to 20,000 liters per day. This innovative solution holds the potential to transform arid regions into water-sufficient areas and has garnered global interest for its ability to harness atmospheric water content effectively.

Project Details

MOFs can hold substantial amounts of water due to their porous structure. The technology has undergone testing in the Arizona and Mojave deserts, demonstrating the ability to harvest water even in environments with 7–20% relative humidity.

The initial prototype involved a plastic box-within-a-box setup, with the internal box containing the MOF opened to the air at night. Water is absorbed by the MOF and released during the day when the internal temperature rises.

The system produced 200–300ml of water per kg of MOF, depending on humidity levels. To enhance efficiency, the design was refined with the addition of solar panels. These panels power small fans that circulate air inside the MOF, and when needed, heat the MOF to release water.

This modification, along with the use of a battery, enables multiple cycles per hour, resulting in almost a tenfold increase in daily water collection per kilogram. The cooperative effect of MOFs allows for effective water capture, making the technology promising for addressing water scarcity in arid regions.

- Air Intake:

- The system takes in ambient air from the surroundings. This air typically contains moisture, even in arid environments.

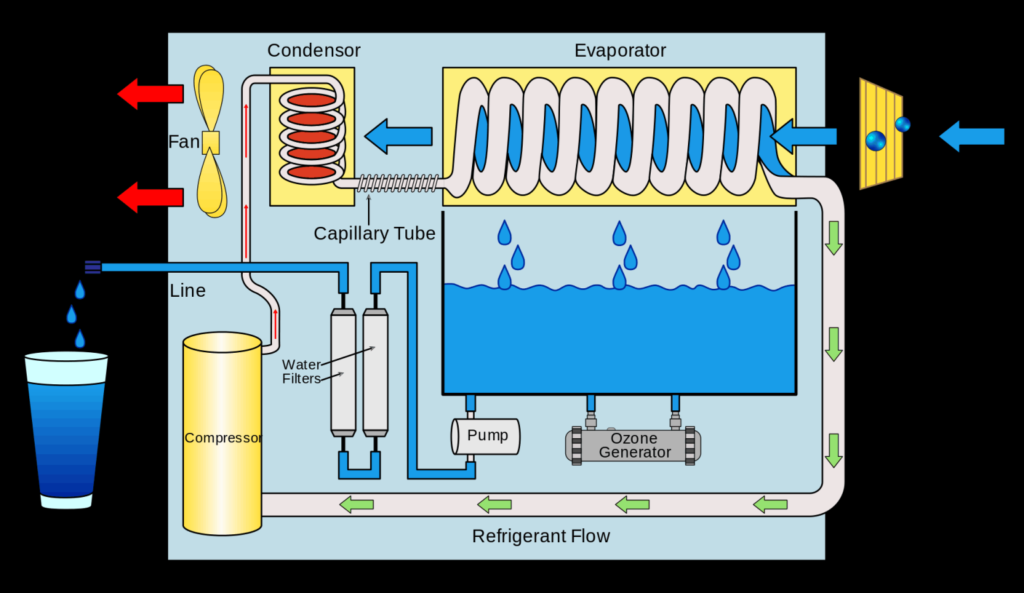

- Cooling Process:

- The collected air is passed through a cooling system, where it undergoes a cooling process. This is often achieved by using a refrigeration cycle.

- Condensation:

- As the air is cooled, its moisture content condenses into liquid water. This is similar to the process of dew forming on a cold surface.

- Water Collection:

- The condensed water is then collected and can be directed into a storage tank or a purification system to ensure it meets the required safety and quality standards for drinking water.

- Heat Exchange:

- The heat generated during the cooling process is usually expelled back into the environment, and the air is returned to its original temperature before being released.

- Renewable Energy Integration:

- In Rainmaker’s case, the cooling system may be designed to be powered by renewable energy sources such as wind or solar energy, aligning with their commitment to sustainability.

- Capacity Control (Optional):

- In more advanced systems, a capacity controller, as mentioned in your previous message, can be incorporated. This allows the cooling capacity to be adjusted based on the availability of steam or other factors, providing a more efficient and adaptable solution.

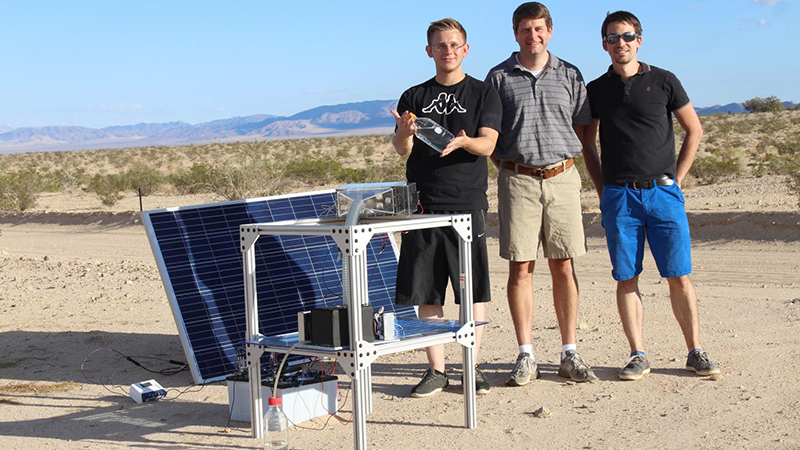

The device harvested water from the arid air of the Mojave Desert, California (Credit: Mathieu Prévot, UC Berkeley)

Reference: Document download