- Project: Powertrain System Battery Cooling

- Cooling Approach: 12V Water Chiller

- Demand: Como Yachts, a Hungary electric boat builder, seeks a 12V liquid cooling solution from Rigid for their high-power powertrain. Concerned about battery coolant temperature in varying climates, the largest 40L battery pack requires cooling and heating to maintain a 25°C temperature during discharge. The client finally chose RIGID’s 1,780W powerful water chiller for his powertrain battery cooling.

- Recommended product: 12V Water Chiller KVB150Z-12

Get Sample Online

Background

Como Yachts, an electric boat-building venture, developing a high-power powertrain system for electric boats. The Hungary company underscores the importance of an efficient cooling solution for the battery coolant. They are looking for a 12V water chiller for the powertrain battery system cooling. The primary concern arises from the diverse climates in which the electric boats may operate, ranging from warmer environments where seawater might be too warm to colder regions where additional heating is necessary.

To address these challenges, the focus is on implementing a closed-circuit system with a heat exchanger. The pivotal requirement is a reliable 12V liquid cooling solution, with a particular interest in RIGID’s offering, the KVB150Z-12 model. The envisioned application involves a sizable battery pack with a 40L coolant volume, aiming to sustain a constant temperature of 25°C during discharge, with an initial coolant temperature potentially reaching up to 35°C.

Considering the variability in water temperatures, the customer explores the possibility of utilizing seawater as an external coolant, emphasizing the need for a cooler if cooler water than seawater is required. Additionally, the inquiry extends to the heat extraction capabilities of the 12V water chiller, the feasibility of seawater cooling for the chiller, and the availability of larger models for potentially higher heat dissipation needs.

In summary, the background underscores the critical need for a sophisticated cooling solution in the electric boat’s powertrain system, with a specific focus on RIGID’s 12V water chiller, to ensure optimal battery performance and temperature management in varying environmental conditions.

Coolants in High-Voltage Battery Cooling Systems – RIGID HVAC

Requirements

- Cooling Requirement: Looking for a 12V liquid cooling solution for a closed-circuit system with a heat exchanger, considering both warm and cold climates.

- Battery Pack Details: The largest battery pack has a 40L coolant volume, aiming to maintain a 25°C temperature during discharge. The initial coolant temperature may be up to 35°C.

- Heat Extraction: Inquiring about the heat extraction capabilities of the KVB150Z-12 model and providing battery heat data for calculations.

- Water Pump Flow: Undetermined at the preliminary phase; emphasis on maintaining battery temperature rather than rapid cooling.

- Seawater Cooling: Consider seawater as an external coolant but explore the need for a cooler if cooler water than seawater is required.

- Cooler Details: Questions about using seawater for cooling the cooler, the availability of larger models (>130W), and the existence of combined cooling and heating functionalities for colder climates.

- Secondary Circuit for Heat Exchanger: Proposing a secondary circuit for the heat exchanger to dissipate heat to water instead of air, housed in a warmer closed machinery compartment.

In a word, the customer aims to cool and heat the battery coolant, considering various climates. The largest battery pack has a 40L coolant volume, and maintaining a 25°C temperature during discharge is crucial.

12V Water Chiller for Electric Boat Battery- RIGID

Cooling Solutions

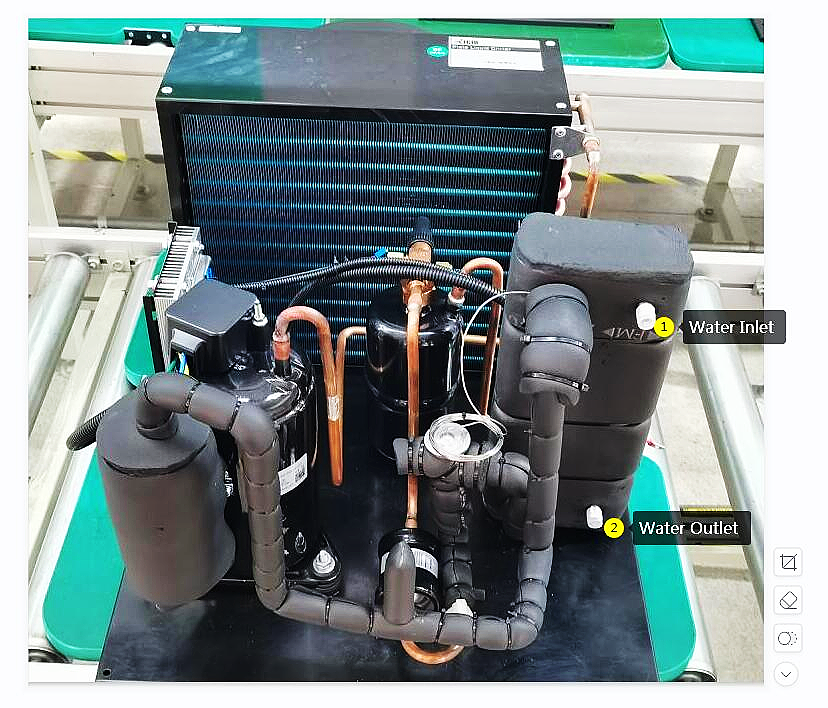

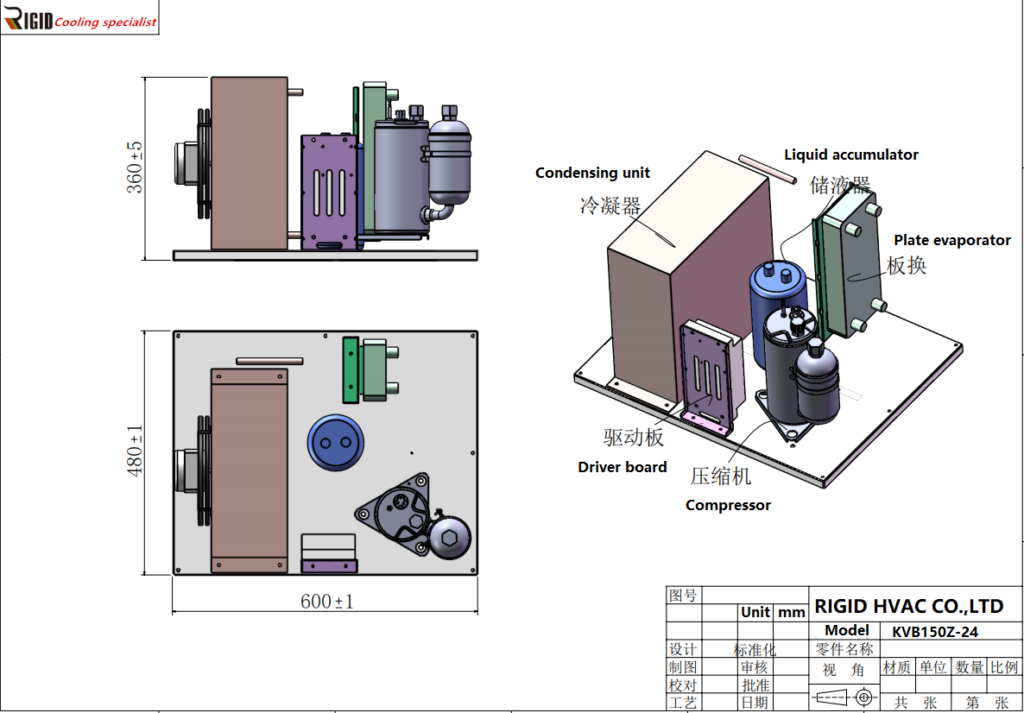

- Product: High Power Water Chiller

- Model: KVB150Z-12

- Power: 12V DC

- R134A Refrigerant

- Nominal Capacity: 1780W

Features:

- Compact in size, yet large in power density

- Light weight extremely portable

- It draws less power and rejects less heat

- Temperature stability with high precision/accuracy.

- Precision Chillers That Work Perfectly In Harsh Environments

DC Water Chiller – KVB150Z (12V / 24V)

Battery Cooling: Challenges and Solutions

A 12V water chiller, such as RIGID’s KVB150Z-12 model, plays a crucial role in a high-power powertrain system by efficiently cooling down the batteries. Here’s an overview of how it performs in this context:

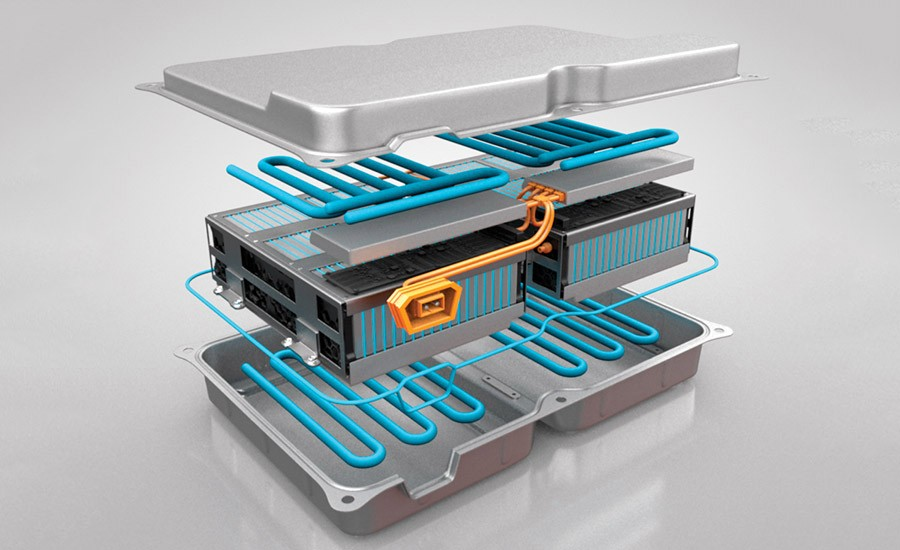

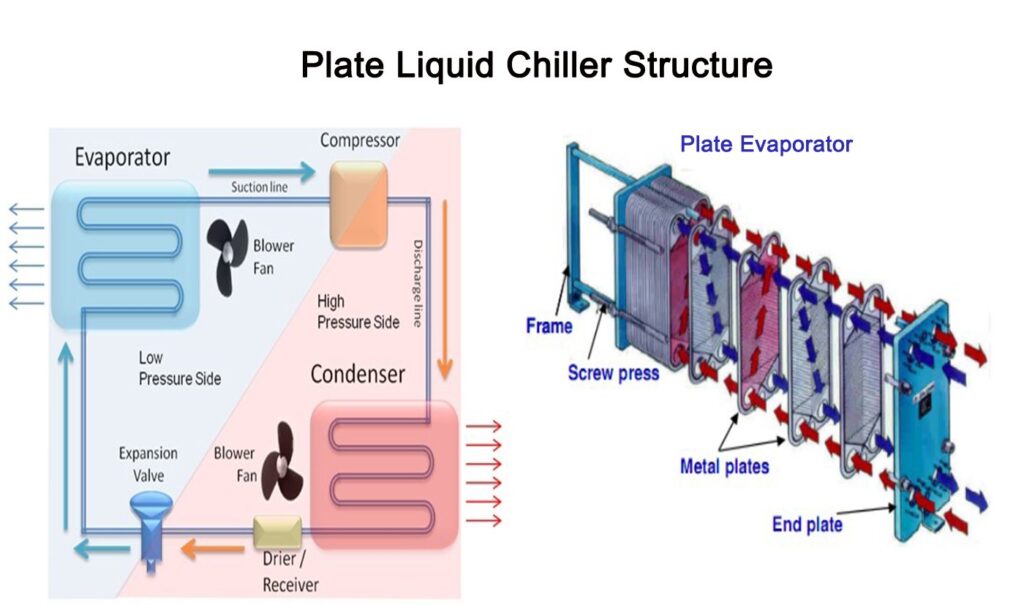

- Closed-Circuit Cooling System: The 12V water chiller is integrated into a closed-circuit cooling system, forming a loop with the powertrain components. This closed-loop design ensures that the coolant circulates within the system, extracting heat from the batteries and other high-power components.

- Heat Exchanger Technology: The chiller incorporates advanced heat exchanger technology. As the coolant flows through the heat exchanger, it absorbs the heat generated by the batteries during operation. This process prevents the batteries from overheating, which is crucial for maintaining their efficiency, longevity, and overall performance.

- Temperature Regulation: The water chiller is designed to regulate the temperature of the coolant effectively. In the case of the electric boat application mentioned earlier, the goal is to maintain a specific temperature, such as 25°C, during battery discharge. This precise temperature control is essential for optimizing the battery’s performance and ensuring it operates within the recommended temperature range.

- Adaptability to Variable Conditions: The chiller is adaptable to varying environmental conditions, addressing concerns related to different climates. It provides the flexibility to cool the batteries efficiently in warmer climates, where sea water temperatures may be elevated, and it can also be part of a system that allows for heating the coolant in colder environments.

- Compatibility with Seawater Cooling: The 12V water chiller may be designed to work with seawater as an external coolant. This feature is particularly beneficial for electric boats, where the availability of seawater provides a natural and effective cooling solution.

- Scalability: Depending on the power requirements and size of the battery pack, the 12V water chiller may be part of a scalable system. Larger models may be available to accommodate higher heat dissipation needs for larger battery configurations in high-power powertrain systems.

In summary, a 12V water chiller in a high-power powertrain system effectively manages battery temperatures through closed-circuit cooling, advanced heat exchange technology, and adaptability to diverse environmental conditions. It plays a crucial role in maintaining optimal battery performance and ensuring the reliability and efficiency of the entire powertrain system.