- Project: Electric Vehicle Battery Cooling

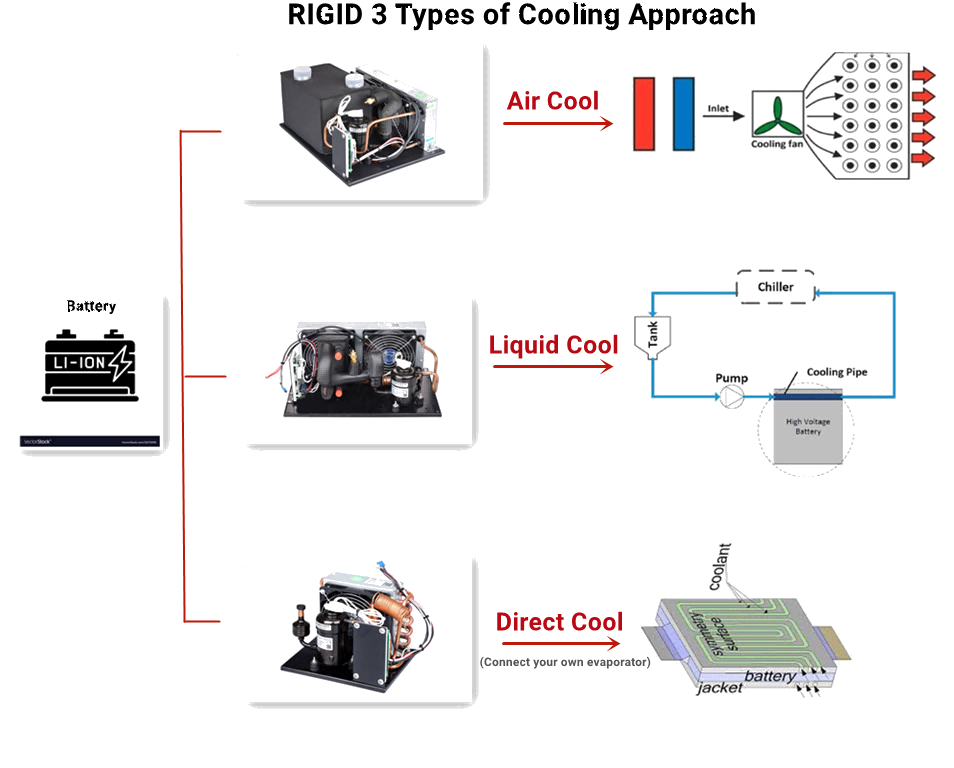

- Cooling Approach: Water to Water Cool

- Demand: The American client is seeking a water-to-water liquid chiller system for cooling lithium batteries in electric vehicles. He requested a cooling up to 800 watts, and compatibility with a 48V DC power source. The system should effectively regulate temperatures on the condenser and evaporator sides, accommodating varying inlet temperatures. Additionally, the customer emphasizes the importance of energy efficiency, with a maximum power consumption of 400 watts, and quiet operation.

- Recommended products: Customized Plate Liquid Chiller

Get A Sample Online

Background

Electric vehicle lithium battery cooling has evolved from basic air cooling to sophisticated liquid cooling systems. The rise of lithium-ion batteries brought attention to thermal management, with liquid cooling emerging as a more efficient solution. Direct and indirect liquid cooling methods are utilized, providing better heat dissipation and temperature control.

Ongoing research explores advanced thermal management technologies, integrating them with vehicle systems for dynamic adjustments. The evolution reflects a commitment to enhancing efficiency, safety, and overall performance in electric vehicle battery cooling solutions.

An American customer is looking for a RIGID water-to-water liquid chiller system to cool lithium batteries in a compact electric vehicle prototype. The system needs to fit within specific dimensions (400mm x 180mm x 300mm) and provide up to 800 watts of cooling while being compatible with a 48Vdc power source.

Key requirements include effective temperature regulation on both the condenser and evaporator sides, accommodating varying inlet temperatures. The customer values energy efficiency (maximum 400 watts) and a quiet operation, aiming to cool batteries and electronics.

After a thorough analysis, the customer chose the customized chiller model DV3830E-P-T(custom) over alternatives like KVB096Z-48, considering factors such as cooling capacity, electrical consumption, and pricing within RIGID’s product range.

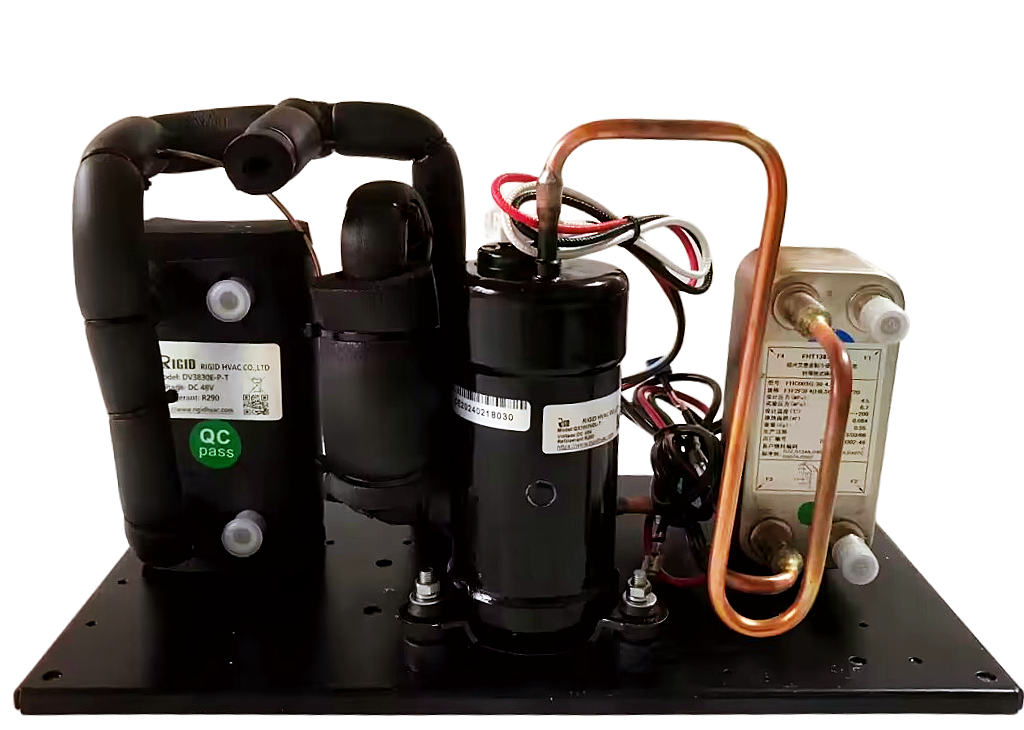

Customized Water Chiller DV3830E-P-T_RIGID.png

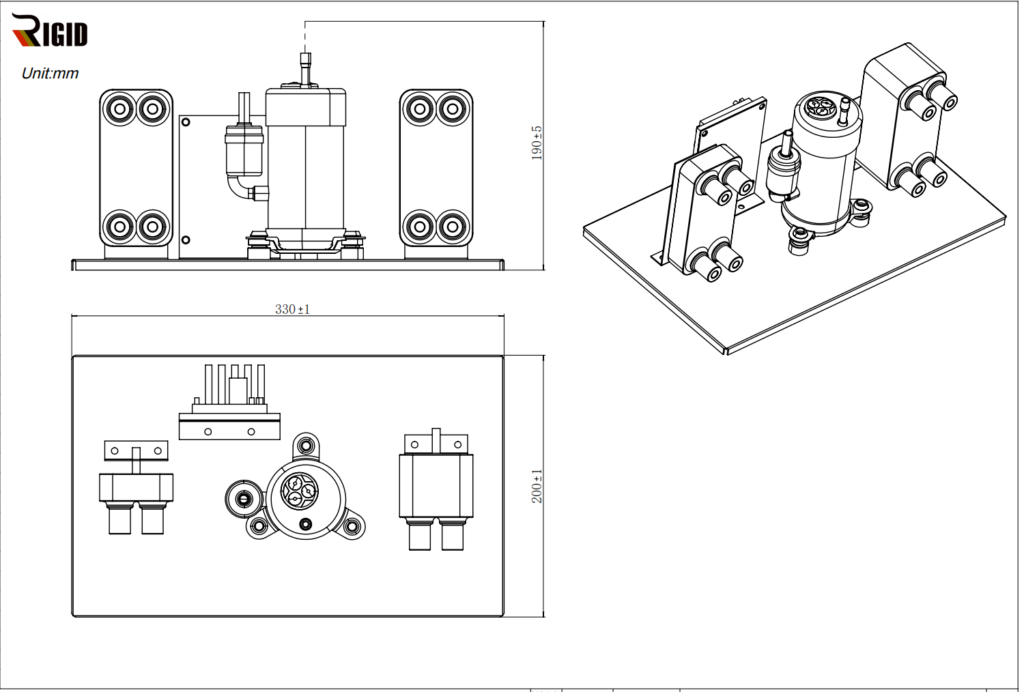

Customized Water Chiller DV3830E-P-T_Drawing

Solution

48V PLATE LIQUID CHILLER: DV3830E-P-T

- Voltage: 48V DC

- Refrigerant: R290

- Net Weight: 6.0kgs (13.23lbs)

- Compressor Cooling Capacity: 750W

- Compressor: 48V mini compressor (Dual-cylinder)

- Applications: Custom Micro Refrigeration Systems that Provide Compact yet Powerful Thermal Management Solutions.

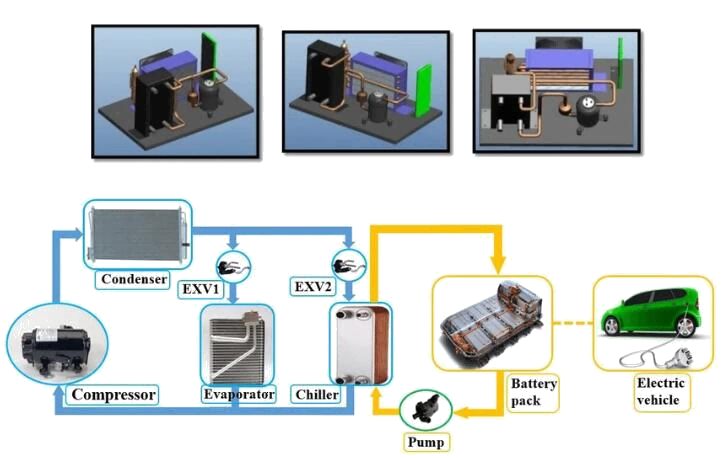

RIGID’s water chillers operate on vapor compression refrigeration principles. The process begins with refrigerant evaporating in the evaporator coil, absorbing heat from water or fluid.

The compressor then raises the refrigerant’s temperature and pressure. In the condenser coil, heat is released to the external environment, causing the refrigerant to condense. After expansion, the low-pressure liquid returns to the evaporator.

Chilled water passing through the evaporator absorbs heat, and the cycle repeats. For specific details or need customized service, do not hesitate to contact us. We are sure you will receive a prompt reply from our engineers.

Features

As a pioneer in micro refrigeration, RIGID has developed a range of liquid cooling chillers/modules based on its miniature bldc compressors, to cater to customers who are aiming to use micro refrigeration modules and products in their equipment. Here are RIGID compact liquid chiller’s features:

- Compact Design: Designed to fit into limited spaces, making them suitable for various applications with size constraints.

- High Cooling Capacity: Despite their small size, compact liquid chillers often offer high cooling capacities to effectively manage heat dissipation.

- Energy Efficiency: Incorporation of energy-efficient components and technologies to optimize cooling performance while minimizing power consumption.

- Temperature Control: Precise temperature control mechanisms to regulate the temperature of the cooling fluid according to specific requirements.

- Quiet Operation: Implementation of noise reduction technologies for quiet and unobtrusive functioning, suitable for various environments.

- Customization Options: Some models may offer customization options to meet specific application needs, allowing users to tailor the system to their requirements.

- Compatibility: Designed to be compatible with various power sources, making them versatile for use in different settings.

- Reliability: Built with durable materials and reliable components to ensure a long operational lifespan with minimal maintenance requirements.

Water to Water Cool Chiller for Battery Cooling

3 Types of Cooling Approach for Battery Cooling – RIGID

Custom and Design

At RIGID, we’re all about quick advancements in small cooling tech and top-notch customization. Our range of compact cooling systems and patented mini compressors fits any need.

Need something specific? Our friendly engineers are ready to craft, design, prototype, validate, and manufacture the perfect solution for you. Whether it’s new tech, product updates, or future projects, our team has you covered. Contact us today for a compact cooling solution tailored just for you!