- Project: Petroleum Automatic Express Analyzer

- Cooling Approach: Stirling Cryocooler (FPSC)

- Demand: The customer, a Greece leading company in environmental and technology fields, seeks an advanced cooling solution for their scientific instruments, including gas analyzers and stack emissions monitoring systems. RIGID’s Stirling Cryocooler is the perfect fit, providing precise temperature control, reliability, compact design, and low maintenance. This collaboration promises to elevate the performance of the client’s instruments, ensuring accuracy and efficiency in their Analyzers and scientific instrument applications.

- Applications: Gas Analyzers, Petroleum Analyzers, Infrared Spectrometers, and other scientific instruments.

- Recommended products: Stirling Cryocooler RS100 Plus

Get A Sample Online

FPSC Stirling Cooler-RS100 Plus

Background

The Greece company, a key player in environmental and technology solutions, is embarking on a project involving Petroleum Automatic Express Analyzer. Recognizing the limitations of traditional compressor chillers, such as imprecise temperature control, high maintenance, and bulkiness, the client has opted to replace them with RIGID’s Stirling Cryocooler.

This strategic shift is driven by the desire to overcome the drawbacks associated with compressor chillers. Traditional systems often struggle with temperature precision, leading to accuracy issues in measurements. Moreover, the frequent maintenance requirements and the bulky design pose challenges in terms of operational efficiency and adaptability.

Enter RIGID’s Stirling Cryocooler—a game-changer in temperature control technology. Unlike traditional compressor chillers, the Stirling Cryocooler offers precise temperature control, ensuring optimal performance and accuracy in scientific instruments. Its long-term reliability minimizes maintenance needs, providing a seamless and efficient solution for client’s applications.

The compact design of the Stirling Cryocooler addresses the space constraints that often come with traditional compressor chillers. This shift signifies the Greece client’s commitment to adopting advanced technology, overcoming the disadvantages of conventional systems, and ensuring optimal performance in their environmental and technology projects.

Oil Analysis Instruments

Stirling Green Power Technology for Petroleum oil analysis instruments

Case Study

The Greece client Utilizes the FPCS module (RS100-Plus) in a device compliant with ASTM D 6371 standards. Requirement for cooler temperature adjustments at specific points during the test. ASTM D 6371 Cooling

Points and Requirements:

- Start of test: -34 °C ± 0.5 °C

- When specimen reaches -20 °C: -51 °C ± 1 °C

- When specimen reaches -35 °C: -67 °C ± 2 °C

Challenge:

- Exceeding the specified transition time requirement of “new temperature reached within 2 min 30 seconds” during adjustments.

Issue Details:

- Current transition time: 5 – 7 minutes.

- Tests were conducted with and without a load (400-gram brass bath).

In this project, the client requests other options for increased cooling capacity. Plus, they also inquire about specific jumper positions that can aid in achieving a faster transition time. Mention of trying various known jumper positions without success.Essential for optimizing device performance by ASTM D 6371 standards. At the same time, seeking guidance from RIGID on increasing cooling capacity to meet transition time requirements.

PETROLEUM & OIL ANALYSIS EQUIPMENT

Solution

100W PLUS STIRLING COOLER

Model: RS100 Plus

- Input power: 24V DC

- Working current: 6A

- Noise: ≤48dB

- External Size: 167× 156 x 291mm (LxWxH)

- Temp Range in Cold Fin (Cold part): -160℃~ 0℃

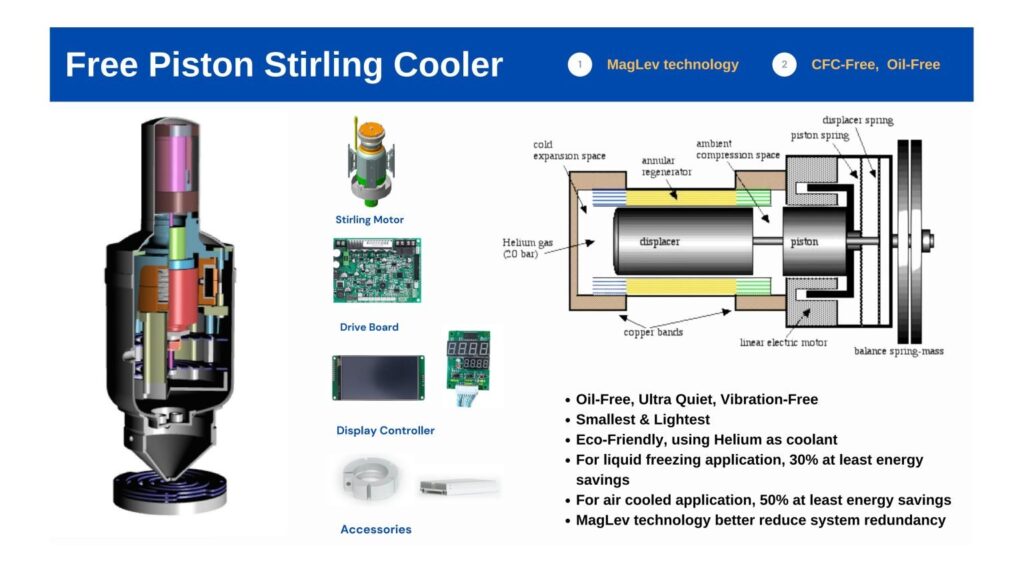

Free Piston Stirling Cryocooler

Stirling Cryocooler RS100 provides accurate low-temperature options in petrochemical and oil refining products

FPSC Stirling Cryocooler Working Principle in Analysis Instruments

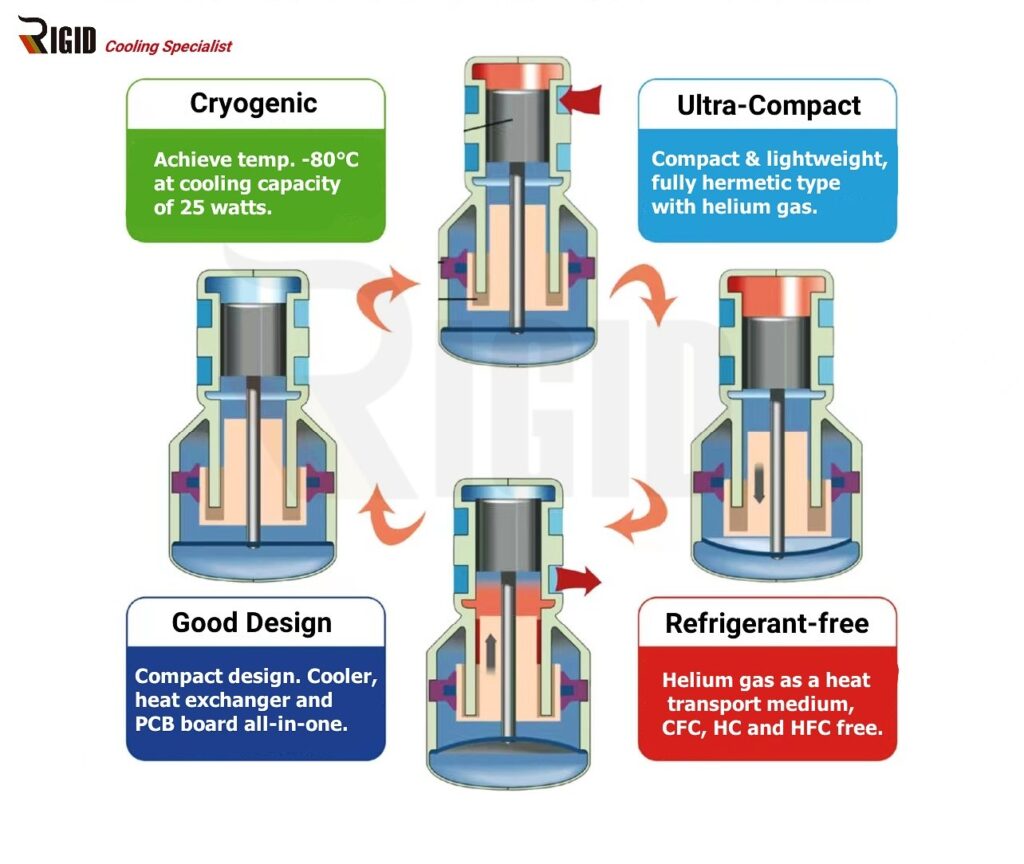

A Stirling cryocooler operates based on the Stirling cycle, a thermodynamic cycle that involves the compression and expansion of a working fluid at different temperatures. Here’s a simplified explanation of how a Stirling cryocooler works in an analysis instrument:

- Compression: The Stirling cryocooler typically consists of a piston within a cylinder. At the compression stage, the piston compresses a working gas (often helium) within the cylinder. This compression increases the pressure and temperature of the gas.

- Transfer: The compressed gas is then transferred to a heat exchanger or regenerator. In the regenerator, the gas releases its heat to the surroundings and cools down. This step is crucial for the overall cooling process.

- Expansion: After releasing heat, the cooled gas is expanded, causing it to absorb heat from the area to be cooled. This cooling effect is utilized to reach low temperatures required for specific applications, such as in analysis instruments.

- Transfer (again): The expanded gas is then transferred back to the heat exchanger or regenerator. This time, the regenerator absorbs heat from the surroundings and heats up.

- Return to Compression: The heated gas is returned to the compression stage, and the cycle

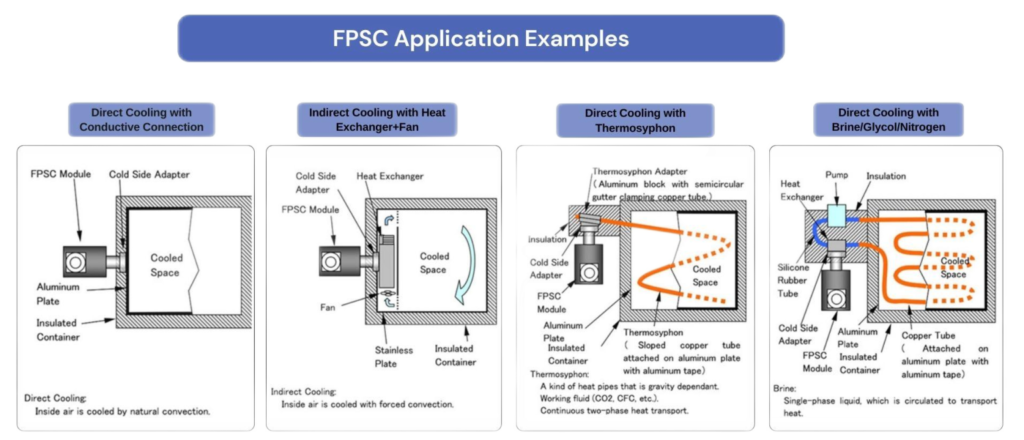

In the context of an analysis instrument, the Stirling cryocooler is integrated to cool specific components, such as detectors or sensors, to achieve the required low temperatures. This cooling is essential in applications like gas analyzers, infrared spectrometers, and other scientific instruments where precise temperature control is necessary for accurate measurements.

RIGID company’s Stirling Cryocooler is known for its efficiency, reliability, and ability to achieve low temperatures without the need for cryogenic fluids. It finds applications in situations where compact and vibration-free cooling solutions are preferred, making it suitable for various analysis instruments.

RIGID Cryocooler’s Advantages

Why Analyzers and Scientific Instruments Require Stirling Cryocoolers?

In a leap towards advancing temperature control technology, RIGID introduces its state-of-the-art Stirling Cryocooler, poised to transform the landscape of gas analyzers, petroleum analyzers, infrared spectrometers, and various scientific instruments. This cutting-edge cooling solution brings a host of benefits that cater to the exacting demands of precision analysis and scientific research.

- Temperature Precision for Unmatched Accuracy

RIGID’s Stirling Cryocooler provides a level of temperature control crucial for scientific instruments where accuracy is paramount. Gas analyzers and petroleum analyzers, among others, rely on precise temperature conditions to ensure accurate measurements. The Stirling Cryocooler delivers a stable and controllable cooling solution, elevating the accuracy of these instruments to unprecedented levels.

- Reliability that Stands the Test of Time

Designed for durability, the Stirling Cryocooler offers a long operating life, making it an ideal choice for scientific instruments used in research, industrial processes, and laboratory environments. Its robust construction ensures uninterrupted and reliable operation, meeting the stringent requirements of continuous use.

- Compact and Portable Cooling Power

The compact size and lightweight nature of RIGID’s Stirling Cryocooler make it a perfect fit for gas analyzers and other field-deployable instruments. This portable cooling solution brings versatility to instruments that need to be agile and adaptable in various settings.

- Vibration-Free Performance for Sensitive Instruments

In scientific instruments like infrared spectrometers, where precision is paramount, vibrations can disrupt accurate measurements. The Stirling Cryocooler, operating without rotating parts, ensures a vibration-free environment, safeguarding the integrity of sensitive measurements.

- Eliminating Cryogenic Challenges

Say goodbye to the logistical challenges of handling cryogenic fluids. RIGID’s Stirling Cryocooler operates without the need for external cryogenic fluids, simplifying instrument operation and maintenance. This innovation streamlines processes, contributing to a more efficient workflow.

- Low Maintenance, High Efficiency

With lower maintenance requirements compared to traditional cooling technologies, the Stirling Cryocooler enhances the overall efficiency of scientific instruments. This low-maintenance design is a game-changer for instruments requiring continuous operation without frequent interruptions.

- Versatility Tailored to Your Needs

The Stirling Cryocooler can achieve a broad range of cooling temperatures, making it versatile for various applications. Whether it’s cooling detectors in gas analyzers or maintaining specific temperature conditions in infrared spectrometers, RIGID’s innovation offers adaptability across scientific fields.

- Energy-Efficient Future-Ready Cooling

RIGID’s Stirling Cryocooler is engineered to be energy-efficient, contributing to overall energy savings in instrument operation. This green technology aligns with the growing emphasis on sustainability, providing a forward-looking solution for the scientific community.

In conclusion, RIGID’s Stirling Cryocooler stands at the forefront of a new era in precision cooling for scientific instruments. Its transformative capabilities in temperature control, reliability, compact design, vibration-free operation, cryogenic fluid elimination, low maintenance, versatility, and energy efficiency make it the go-to choice for innovators and researchers pushing the boundaries of scientific exploration.

For more information on how RIGID’s Stirling Cryocooler can elevate your instruments to new heights, please contact us.

Why Did the Greek Client Choose to Replace Compressor Chillers with RIGID’s Stirling Cryocooler in Oil and Petroleum Analyzers?

Primary Reasons: The decision to replace traditional compressor chillers stems from their limitations, including imprecise temperature control, high maintenance, and bulkiness.

This strategic shift is motivated by the goal of overcoming the drawbacks associated with compressor chillers. Traditional systems often struggle with maintaining precise temperatures, leading to inaccuracies in measurements. Additionally, the frequent maintenance requirements and bulky design pose challenges in terms of operational efficiency and adaptability.

Introducing RIGID’s Stirling Cryocooler—a revolutionary technology in temperature control. Unlike traditional compressor chillers, the Stirling Cryocooler provides precise temperature control, ensuring optimal performance and accuracy in scientific instruments. Its long-term reliability minimizes maintenance needs, offering a seamless and efficient solution for the client’s applications.

The compact design of the Stirling Cryocooler addresses the space constraints typically associated with traditional compressor chillers. This innovative choice not only enhances performance but also optimizes space utilization for the client.

Crocooler’s Advantages in Oil and Petroleum Analyzers

- Precise Temperature Control: Stirling Cryocoolers provide accurate and precise temperature control, crucial for maintaining optimal conditions in oil and petroleum analyzers. This precision enhances the accuracy of measurements and ensures reliable results.

- Long-Term Reliability: Stirling Cryocoolers are known for their durability and long operating life. In the demanding environment of oil and petroleum analysis, having a reliable cooling solution is essential for continuous and uninterrupted operation.

- Compact Design: The compact and lightweight nature of Stirling Cryocoolers is advantageous in applications where space is limited, a common consideration in oil and petroleum analyzer setups. The efficient use of space allows for more flexibility in the design and placement of analytical equipment.

- Vibration-Free Operation: Stirling Cryocoolers operate without the need for rotating parts, resulting in a vibration-free performance. This characteristic is crucial in oil and petroleum analyzers where precise measurements are sensitive to vibrations.

- No Cryogenic Fluids Required: Stirling Cryocoolers operate without the need for external cryogenic fluids. This eliminates the challenges associated with handling and replenishing cryogens, making the operation of oil and petroleum analyzers more straightforward.

- Low Maintenance: Stirling Cryocoolers generally have lower maintenance requirements compared to traditional cooling technologies. This is particularly advantageous in oil and petroleum analyzers, where consistent and reliable performance is essential.

- Energy Efficiency: Stirling Cryocoolers can be designed to be energy-efficient, contributing to overall energy savings in the operation of oil and petroleum analyzers. This aligns with the industry’s focus on sustainability and cost-effectiveness.

In summary, the advantages of Stirling Cryocoolers, including precise temperature control, long-term reliability, compact design, vibration-free operation, no reliance on cryogenic fluids, low maintenance, and energy efficiency, make them well-suited for the demanding requirements of oil and petroleum analyzers.