FPSC Cryocooler

FPSC Cryocooler

Free Piston Stirling Cryocooler is a type of cooling system that doesn’t use a compressor. Instead, it cools by repeatedly compressing and expanding helium gas. Helium is a safe gas that doesn’t harm the environment. RIGID Cryocooler has been widely used in Bio-science, military, laboratory devices, analytical instruments and vaccines at low temperatures. The Sterling engine is a new technology for small and deep freezing, quickly reaching temperatures as low as -120℃ in just a few minutes.

- RS40

- RS80

- RS100

- RS100 Plus

Cryocooler: State-of-the-Art Fast and Deep Freezing!

RIGID, one of the leading Chinese companies in terms of innovation, has developed a Free Piston Stirling Cryocooler – FPSC. The Cryocooler brings the whole product to a new level, where it can save a lot of energy and greatly improve efficiency.

The FPSC Cryocooler has several advantages over refrigerated compressor systems. They can achieve very low temperatures -86℃ (Max -160℃), have no moving parts except for the pistons, which reduces the risk of failure, and have a relatively high efficiency. They are used in a variety of applications, including Food, Cold chains, Laboratory Equipment, Automatic Devices, Petrochemicals & Oil, Scientific Research, Life Science, Medical Imaging, and the cooling of electronic components.

The RIGID Cryocooler is a cooling system that has only two moving parts. The Sterling unit has a stainless steel housing and all sensitive components are hermetically sealed inside. This means it costs less to maintain. PFSC continuously repeats gas compression and adiabatic expansion and uses natural helium gas as a refrigerant. Helium is a very safe gas. It is completely harmless to our environment.

Technical Data

Click picture below to watch the video!

Environmentally Friendly

Free Piston Stirling Cryocooler adopts helium, a naturally occurring gas that is harmless to the human body, does not deplete the ozone layer, and does not contribute to global warming.

Super Cooling Capacity

The FPSC can easily reach temperatures below -99℃ (on the cold head). This is extremely difficult to achieve with vapor compressors. The Stirling cryocooler is highly efficient. It can be up to 6 times higher than thermoelectric (Peltier) coolers.

Lightweight & Compact Size

Weight: 6~7 kgs (half the weight of compressor systems) The FPSC is suitable for use in life science, laboratory, medical, food, small countertop freezers, portable refrigerators, and special low-temperature applications.

Precise Temp. Control

The FPSC is continuously modulated by electronic circuitry, not by on/off cycling as in compressor systems. The control circuits maintain a constant set temperature, allowing for extremely precise temperature control, ideal for sensitive applications.

Energy Savings

The RIGID FPSC consumes 40W~100W of power and is compatible with a variety of power sources such as 12V or 24V direct power, photovoltaic (solar cells), or in-house generators, as well as 110/220VAC power.

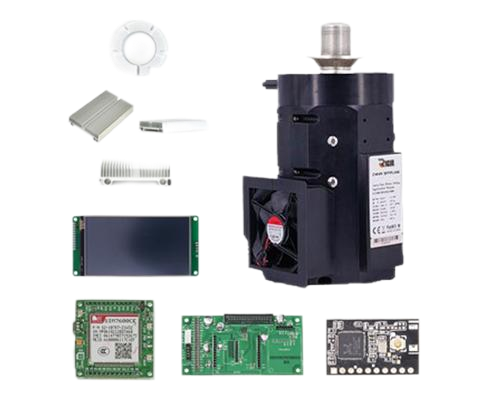

FPSC Stirling Model

40W STIRLING CRYOCOOLER

Model: RS40

- Input power: 12V DC

- Working current: 6A

- Noise: ≤38dB

- Size: ODФ86mm x Length 260mm

Temp Range in Cold Fin (Cold part): -100℃~ 0℃

80W STIRLING CRYOCOOLER

Model: RS80

- Input power: 24V DC

- Working current: 6A

- Noise: ≤48dB

- Size: ODФ86mm x Length 270mm

Temp Range in Cold Fin (Cold part): -120℃~ 0℃

100W STIRLING CRYOCOOLER

Model: RS100

- Input power: 24V DC

- Working current: 6A

- Noise: ≤48dB

- External Size: 132×132x336mm(LxWxH)

Temp Range in Cold Fin (Cold part): -150℃~ 0℃

(No KF50 vacuum flange)

100W PLUS STIRLING CRYOCOOLER

Model: RS100 Plus

- Input power: 24V DC

- Working current: 6A

- Noise: ≤48dB

- External Size: 167× 156 x 291mm (LxWxH)

Temp Range in Cold Fin (Cold part): -160℃~ 0℃

(Included KF50 vacuum flange)

Advantage

High Capacity

High Efficiency

High Reliability

Miniature Size

Low Weight

Low noise

Application

Free Piston Stirling Cryocoolers are complete CFC-free systems, using natural Helium gas. They are small, portable, and are widely used for precise temperature control for under -160℃ max. The default version of Stirling coolers includes pistons, heat exchangers, and compression spaces. But we see technological advancements in all industries, such as Biotech, Pharmaceutical, Food, Energy, Chemical, Medical, Bio-Science, logistics, and Metrology.

Isovolumetric Exothermic Process

Both pistons move in the same direction at the same time and the volume of gas remains constant until the compression piston reaches its dead center. As the gas passes through the regenerator, the heat is transferred to the packing, the temperature is reduced, and the pressure is also reduced.

Isothermal Compression

The compression piston moves while the expansion piston does not. Gas is isothermally compressed, compression heat is transferred through the cooler to the coolant (water or air), the temperature is maintained, pressure is increased, and volume is decreased.

Isothermal Expansion Process

The compression piston stops at the stop point while the expansion piston continues to move to the stop point. The gas is isothermally expanded and absorbs a certain amount of heat (cooling capacity) from the low-temperature heat source (cooling object) through the cold heat exchanger. The volume increases and the pressure decreases.

Constant Volume Heating Process

Both pistons move in the same direction at the same time to the stop point, the gas volume remains unchanged and returns to the starting position. As the gas passes through, it absorbs heat from the regenerator packing, and the temperature increases while the pressure increases.

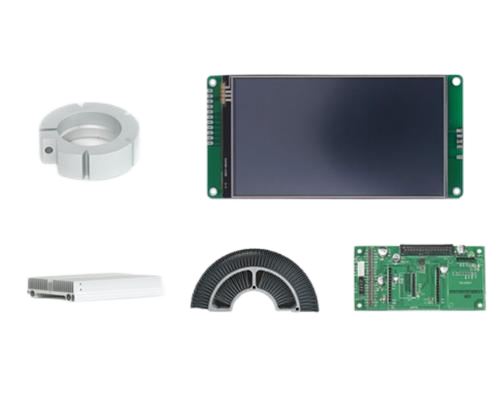

Features

High Durability By Linear Motor

RIGID Free Piston Stirling Cryocooler includes two pistons (pistons and balancing float) in the top compression chamber. The piston is driven by a linear motor, which sends helium gas to the balancing float (80 Hz).

High Precision Controller By RIGID Tech

Free Piston Stirling Cryocooler comes with a main drive board and display controller. Supports wide range control and accuracy to ±1°C. RIGID Stirling Cryocooler, drive board, temperature control, and fan are integrated into one unit.

Eco-friendly Coolant By Using Helium

No Oil, No CFC. MagLev technology. It is a new type of completely CFC-free, high-efficiency, energy-saving, and environmental-protection Cooler, which uses a small amount of helium as the coolant.

E-shop

Sample products are available from our online store. Your order will be proceeded in 24hrs and delivered by DHL/UPS/FedEx.

Free Piston Stirling Cryocooler Projects

Medical & Laboratory

Portable Freezer

Analysis Device

Vaccine Storage

Scientific Research

Semiconductor & Chip

FAQs

1. What is a Free Piston Stirling Cryocooler?

FPSC is a kind of Stirling Cryocooler with a small footprint but efficient performance. RIGID Stirling cooler is a type of cryocooler that uses the Stirling cycle to achieve cooling. The Stirling cycle is a thermodynamic cycle that involves the compression and expansion of gas to produce a temperature difference. In a Stirling cryocooler, this cycle is used to produce a temperature difference between two regions, which can then be used to achieve cooling.

2. How does a Stirling Cryocooler work?

A Stirling Cryocooler utilizes the Stirling cycle to convert electricity into the movement of heat from the cold tip towards the heat rejecter.

3. What's Stirling engine used for?

Stirling engines are energy conversion devices used as prime movers, refrigerating, or heat pumps. Currently, they are used commercially as cryogenic cooling systems, deep and fast freezing, and cold chain logistics, and are under development as low-noise, low-emission automotive engines.

4. How cold can RIGID Stirling Cryocooler get?

Temperature down to -90℃ in a few mins. And with our largest model RS100, the maximum temperature can reach to minus -150℃.

5. Which gas is used in Stirling Cryocooler?

Although air is the traditional working fluid for Stirling engines, Hydrogen and Helium are also employed for improved performance due to their better thermal properties.

6. How long can a Stirling Cryocooler run?

The Cryocooler design life is 5 years, and this is the recommended lifetime, although the current mean time to failure (MTTF) is over 200,000 hours, roughly 23 years.

7. What maintenance Stirling Cryocooler is required?

The Cryocooler components are enclosed in a welded pressure vessel and there is no way to access them. There is no maintenance required on the cryocooler. We do recommend keeping the air fins free of debris on units that have cooling fins.

8. What maintenance Stirling Cryocooler is required?

The Cryocooler components are enclosed in a welded pressure vessel and there is no way to access them. There is no maintenance required on the Cryocooler. We do recommend keeping the air fins free of debris on units that have cooling fins.

9. What is the difference between a Free Piston Stirling Cryocooler?

We have four models of Stirling Cryocooler:

10. What's the power of Free Piston Stirling Cryocooler?

- RS40:12V DC

- RS80:24V DC

- RS100:24~30V DC

- RS100 plus:24~30V DC

11. Where can I buy Stirling Cryocooler?

You can purchase the Sterling cooler directly from our online shop.

12. What are the difference between RS100 and RS100 Plus?

- Cold head temperature: (Data from laboratory)

- RS100: 0℃ ~ -150℃

- RS100 Plus: 0℃ ~ -160℃

2. Cold head temperature:

- RS100: No KF50 vacuum flange

- RS100 Plus: Included KF50 vacuum flange

RS100 Plus adopts a standard KF50 flange which is specially used in vacuum applications.